The annual number of parcels sent worldwide already exceeds 100 billion and continues to rise, and practically all of them carry a shipping label. Achieving economies in the labeling process, which plays a critical role in the logistics chain, gives rise to substantial competitive rewards at the same time. These benefits are multiplied by the HERMA InNo-Liner system, for which a patent application has been filed. It completely eliminates the hitherto essential siliconized liner.

- The new labeling system enables more eco-friendly packaging through shipping labels without any liner material.

- The patented self-adhesive material, which is not at all sticky at first, becomes highly adhesive in a fraction of a second as it is dispensed and activated by a special micro-atomizer.

- The linerless HERMA InNo-Liner system can apply labels to shipping cases of different sizes being fed to the applicator in any sequence.

- Among the linerless systems known to HERMA, this is the first solution of its kind worldwide that satisfies the strict requirements imposed by logistics and distribution centres.

Both economically and ecologically convincing advantages

It’s not only a cost-cutting game changer from the perspective of logistics and shipping, but also actively contributes to protecting the environment.

Because the HERMA InNo-Liner system can drastically minimize the entire climate-relevant CO2 footprint of labels – by managing without any liner material. A huge amount of waste is avoided. Around the world, labeling is an activity which at present generates millions of tons of liner that is completely useless once the labels have been applied. Avoiding this residual material altogether also entirely eliminates the currently essential and expensive disposal and recycling operations.

Users, label printers and environmental campaigners have other reasons to be pleased as well – in the absence of a liner, each roll can accommodate more labels, so that both the shipping weight and the necessary warehousing space are reduced. This material offers absolute process reliability. Its stability has been verified both in the climate lab and in practical printing and processing tests.

The HERMA InNo-Liner system easily achieves the generally required cycle speed for A5 or A6 labels, and the labels can be preprinted in color if necessary. As regards affordability, moreover, the cost is much the same as that of a conventional self-adhesive label. The cost of disposing of liner, however, is completely eliminated.

In a nutshell: Benefits compared to self-adhesive labels

- No liner waste and therefore no waste disposal costs

- Lower transport volume and weight and therefore reduced CO2 emissions

- More material on each roll and therefore fewer roll changes

- Less material consumption (No label feed or waste stripping)

- Avoidance of torn backing paper

- Variable label length

- Free from silicone

- Less warehousing space

Further CO2 savings in the process

The saving of the release liner alone ensures 45% less CO2 emissions compared to self-adhesive labels.

In addition, there are further CO2 savings in the process. For example, further material savings are achieved by eliminating matrix waste at the label material. For a narrow roll width of 333mm, this results in a saving of approx. 12%. Further savings of approx. 3% can be achieved through reduced storage and handling costs. Overall, the HERMA InNo-Liner system can save around 60% of CO2 compared to a classic self-adhesive label.

Of course, this is only a rough sample calculation based on common dimensions. Our experts will be happy to advise you and calculate the saving potential for your specific application. Please contact us non-committal using the contact form.

Better than conventional linerless

Although linerless applications already exist, including in the form of self-adhesive receipts or vouchers and sealing labels, their serious shortcomings have condemned them to a niche existence. Because these types are sticky from the outset and wound on rolls, their surface is often siliconized and therefore incompatible with printing inks – and thermal printers can produce only black or single-color lettering and images. Other systems, such as those that are activated by heat, suffer from inherent speed limitations.

No silicone is required for the HERMA InNo-Liner system, as activation only takes place during dispensing. With the restriction to siliconized thermal paper lifted, another major advantage lies in the diverse range of label materials that are available to users and label printers.

In a nutshell: Benefits compared to siliconized linerless

- Highly diverse materials

- Multicolor printing possible

- Various printing techniques possible

- Free from silicone

- Permanent final adhesion

- Accelerated cycle speeds

- Lower costs

- Cut edges do not stick to each other

- Reduced downtimes

Ideal for use as shipping labels

The Parcel Shipping Index has predicted that 13 of the most active parcel shipping nations alone, including Germany, the United Kingdom, France, Italy, the USA, China and Japan, will be generating an annual volume of 100 billion parcels in 2020. (The Parcel Shipping Index is compiled regularly by the franking and mailing specialist Pitney Bowes, and was most recently published in August 2018.) Practically all of these parcels will be carrying a fairly large shipping label. According to the German Federal Association for Parcel and Express Logistics (BIEK), more than ten million shipping labels are used per day in Germany alone.

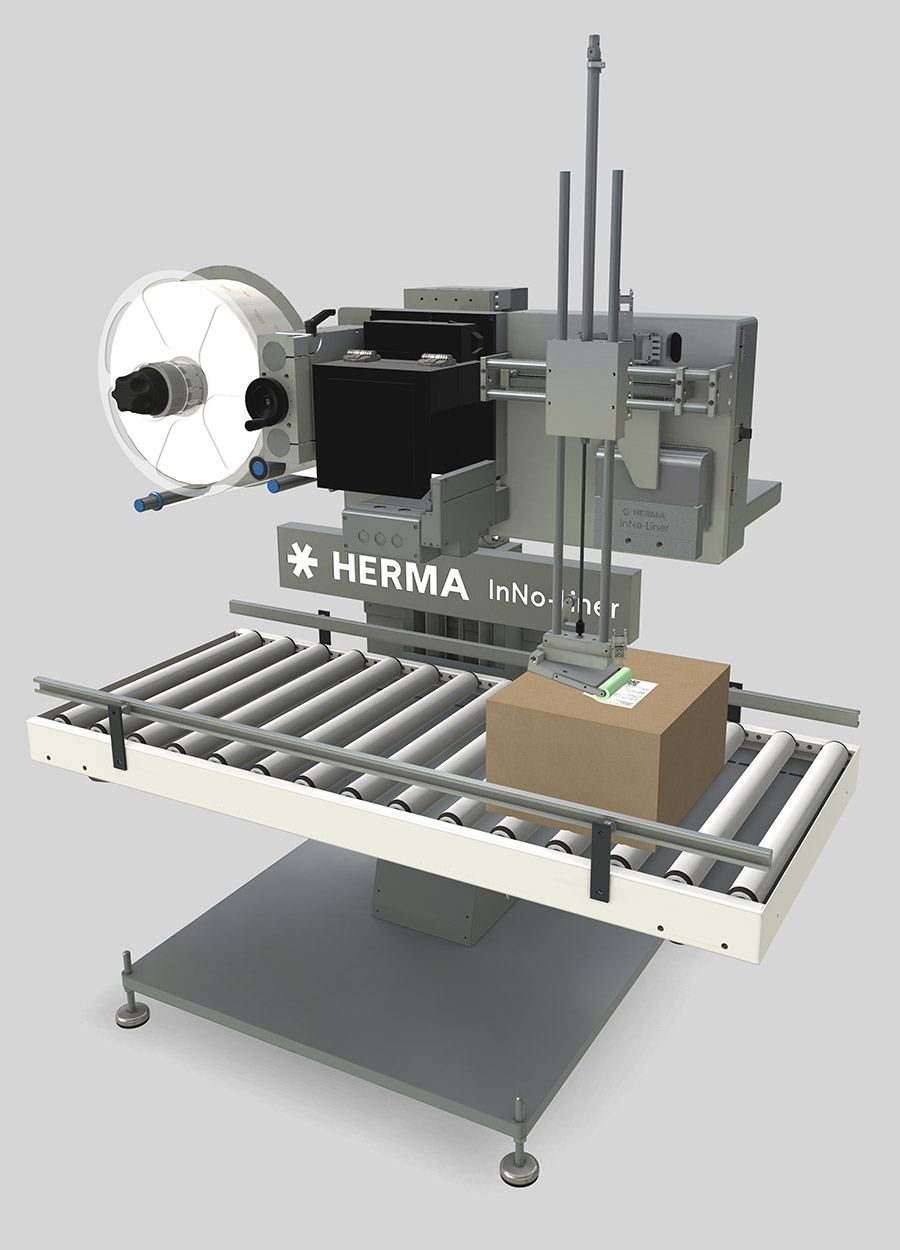

Among the products known to us, the HERMA InNo-Liner system is the first practical solution of its kind worldwide that satisfies the cycle speeds and other requirements imposed by logistics and distribution centres. On top of that, the label stock is compatible with multi-color preprinting. Thanks to the sensor control for variable labeling heights, the system can apply labels to the top of shipping cases of different heights that are fed to the applicator in any sequence. When it comes to print & apply applications, there are therefore many reasons to switch to the HERMA InNo-Liner system immediately.

"Awarded" - Voices from the professional world

German Packaging Award 2019

The HERMA InNo-Liner system has won over an experienced jury: the system has now won the German Packaging Award in the category sustainability. The German Packaging Award is regarded as the most prestigious packaging performance competition in Europe. Held under the patronage of the Federal Ministry for Economic Affairs and Energy, an independent jury with members from trade associations, companies, trade, and research had analyzed and judged submissions from 14 countries. In the end, 34 innovations from Germany, Switzerland, Spain, and Sweden won prizes in the award’s ten categories.

Many positive feedback from the specialist audience

At Labelexpo in Brussels and Fachpack in Nuremberg, where the system celebrated its world premiere in autumn 2019, product demonstrations were constantly surrounded by people. Among the visitors were many label users from well-known companies and label printers, but also machine builders and so-called system integrators who design and implement complete logistics solutions. Many have confirmed that this system has what it takes to become a game changer, a solution that can actually revolutionize a market or an application.

HERMA as a system provider - with full commitment to innovation and sustainability

The InNo-Liner system was jointly developed by all three HERMA divisions: Labeling Machines, Self-adhesive Materials, and Labels. As a result, the comprehensive chain of know-how in self-adhesive technology could and can be fully utilized - HERMA has had experience in this field since its foundation in 1906.

All the more than 1,000 employees at HERMA are committed to making HERMA and its products better and better and to constantly developing them further - for and with our customers.

We have recently developed a number of innovations that show how labels can help make packaging and recycling processes much more sustainable. Label papers made of grass or recycled material, special wash-off adhesives or the thin range with particularly thin, economical materials are just a few examples.

Technical details

The HERMA InNo-Liner system is characterized by the fact that the labels do not require a liner. Made from paper or film, liner materials are used to cover the adhesive side of labels. Although the paper materials are likewise wound on rolls, they are not sticky because the adhesive is not activated until later.

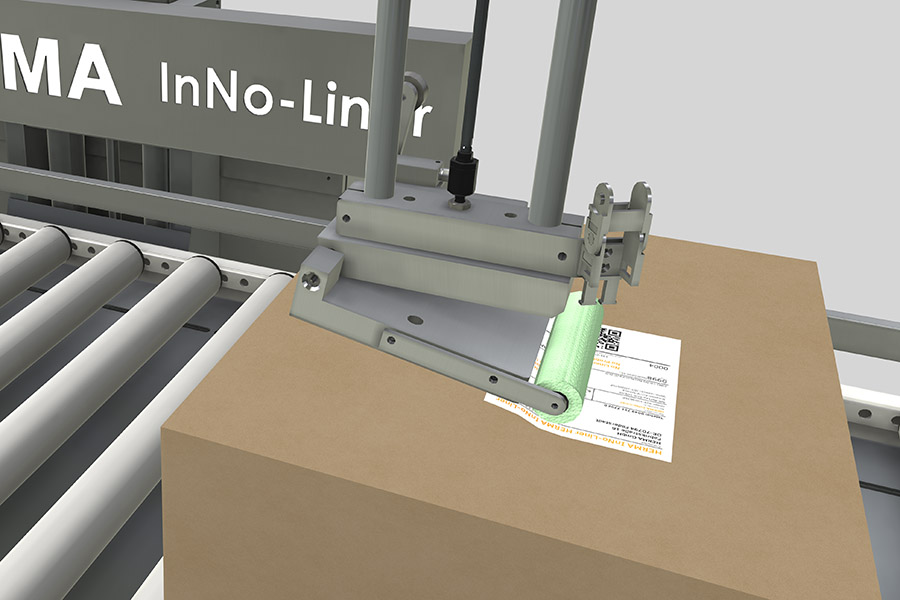

Not until the label is dispensed does the micro-atomizer activate the adhesive by applying a precise dose of water. The strength of the immediate, uniform and tenacious adhesion enables the label to hold so fast that any attempt to detach it from the parcel inevitably tears fibres from the packaging material as well.

In detail it goes like this: The initially non-sticky label is transferred to a tamp pad, which is equipped with a box height sensor and a linear unit. First, a water-only activation unit performs a transverse motion underneath the label, where it activates the adhesive with a highly consistent spray of micro-atomized water. Then the linear transfer unit automatically moves the tamp pad, with the activated label, to the required labeling height for the next case in the line. Thus, the system can apply labels to the top of shipping cases of different heights that are fed to the applicator in any sequence.

The activation medium used for the adhesive, which is not at all sticky at first, is demineralized water – water in its purest form. It ensures consistently high process quality, irrespective of the natural water hardness fluctuations encountered at different operating sites. Water consumption is minimal, especially since any unused water is filtered and recycled in the system. The activation unit can be cleaned as required.

Necessary manual intervention consists largely of renewing label reels. For printing variable data on the labels, both thermal transfer and direct thermal options are available. Labels can also be preprinted in color with conventional techniques.

HERMA‘s InNo-Liner system is based on a specially developed technology. The extremely strong adhesion is made possible by a special multi-layer adhesive, which HERMA is seeking a patent for – along with the micro-atomizer which was specially developed for the system. The interaction of the atomizer and adhesive is crucial to process reliability during the dispensing operation.

Thanks to its universal knowledge base, HERMA offers an end-to-end solution from the outset – linerless label stock alongside an innovative labeling system. Users instantly benefit from the peace of mind afforded by integrated performance, while label manufacturers are presented with new selling points for marketing their compelling solutions.

HERMA InNo-Liner Leaflet

Detailed information clearly arranged can be found in the download brochure.