Ethernet/IP Schneider

With the help of the following information you can integrate one or more HERMA 500 IE applicators into a higher-level controller – in this case Schneider Electric PacDrive LMC101C.

The steps required in the relevant development environment and the initialization (initial configuration) of the underlying parameters in the HERMA 500 IE are described.

You can find all information and sample projects to download here

You can get more detailed information from the above download, incl. FAQs.

Prerequisites

- “Logic Builder” by Schneider.

- Connection of the HERMA 500 IE to the customer’s controller.

- Optional connection of further applicators HERMA 500 IE:

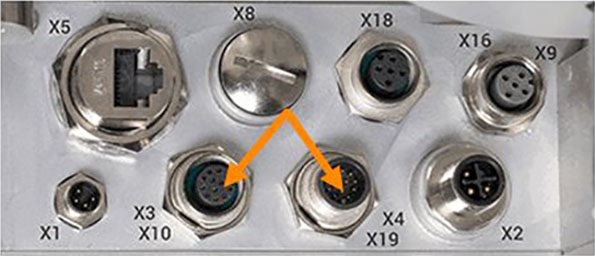

V1 (until end of 2021)

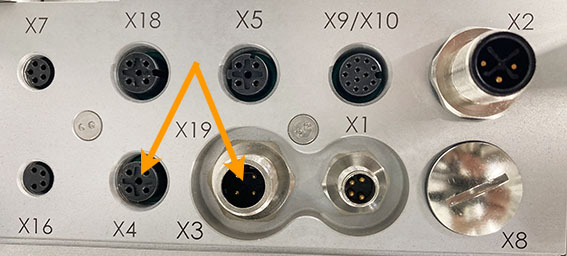

V2 (Facelift) as of 2022

Sample project

To test the successful integration, we provide you with sample projects that let you learn step by step how to switch on the HERMA 500 IE, dispense labels with it and change parameters, for example.

This project is included in the download offered above, as well as explanations supplemented with various screenshots, examples, exercises and a video tutorial.

Integrating the applicator into the PLC

Schneider Electric PLC with Logic Builder

The library supplied in the sample project controls the data traffic between the PLC and HERMA 500 IE. It must be instantiated once for each connected HERMA 500 IE and called separately under “Main POU” in the program. Each instance of the library also contains a data block for the respective HERMA 500 IE. The library is compatible for use with Logic Builder V4.41 or higher and Machine Expert V2.1 or higher.

The library is write-protected and cannot be changed.

Preparations

The following settings must me configured prior to the first connection to the PLC:

- Under “Advanced settings --> Fieldbus settings --> Fieldbus selection (parameter 650)”, you must set “Ethernet/IP”.

- In Parameter 651 activate the EtherNet/IP communication protocol..

- In Parameter 652 set the desired IP Address. The same IP address must be used in the hardware configuration in the PLC.

To access this parameter, you must be logged in as an administrator.

To apply the data and start in the new mode, you must briefly disconnect the HERMA 500 IE from the power supply (switch the HERMA 500 IE off and on again).

Adding functions and data blocks to your project

The sample project provided by HERMA is intended for an application with three HERMA 500 IE devices. If you are only using one HERMA 500 IE, you only have to copy the functions, data blocks and variables for “E1” (applicator 1). Repeat the steps for E2, E3 to En, if you are using more than one HERMA 500 IE applicator in your device.

- Open your actual project in your programing environment.

- Open a second instance of the programing environment and open the sample project provided by HERMA.

- Copy all the relevant global variables from the sample project to your project. The sample project contains the global variables for three HERMA 500 IE devices. Adapt the number of variables to the number of HERMA 500 IE devices in your project.

- Copy the required functions and add them to your project. The sample project contains three “H500_Init_En” init functions for three HERMA 500 IE devices. Adapt the number of init functions to the number of HERMA 500 IE devices in your project.

- Open “SR_Main” and copy the variable definition and the source code to your project. This is where you create instances of the data block (all the parameters) and the function responsible for the communication, data exchange and the processing of the parameters and the exchanged data between HERMA 500 IE and the PLC.

- Open the library manager in your project and open the library repository. Install the library for the EtherNet/IP protocol from the sample project folder. Following the installation, add the library to your project. The library contains the communication function and the data block with the parameters that you instantiated in the previous step.Install the library for the EtherNet/IP protocol from the sample project folder. Following the installation, add the library to your project. The library contains the communication function and the data block with the parameters that you instantiated in the previous step.

You can find a more detailed description of the content below.

You can find an overview of the data block below. Following these steps, you can continue with the hardware configuration for the fieldbus.

PacDrive LMC101C Logic Builder sample setup for configuration

Firstly, you import the current EDS file for the network controller fieldbus into the project (the EDS file is located in the sample project folder). To install the EDS file, go to the main menu in the project view and choose “Tools --> Device Repository --> Install”.

Add an EtherNet/IP scanner to your project. To do so, proceed as follows: Devices view --> right-click the controller --> Add device --> Fieldbus --> EtherNet/IP --> EtherNet/IP Scanner.

Once the EDS is installed, add an EtherNet/IP Remote Adapter to your project. To do so, proceed as follows: Devices view --> right-click EtherNet/IP Scanner --> Add device --> Fieldbus --> EtherNet/IP --> EtherNet/IP Remote Adapter --> HERMA500.

Hint: If HERMA500 is not visible in the list of devices click on the Vendor drop down menu and choose “all vendors”.

The Remote Adapter for the HERMA 500 IE should now be displayed. Repeat the steps for E2, E3 to En, if you are using more than one HERMA 500 IE applicator in your project.

You must now set the IP addresses of the EtherNet/IP-Scanner and the HERMA500 Remote Adapter. The IP addresses must be in the same range as those of the PLC.

For I/O mapping, use the global variables defined earlier.

8 bytes in the input range

8 bytes in the output range

If you are using more than one HERMA 500 IE device, repeat this step accordingly. Before you connect the HERMA 500 IE to the PLC, you must assign the device with the same name and IP address as the one in the hardware configuration in your project.

Now connect the HERMA 500 to the PLC. Translate the project and download it to the CPU. You can now go online and test the availability of the participants. Once you have successfully completed the hardware configuration, the EtherNet/IP connection should function.

If everything is configured correctly the first five bits of the communication status structure will be TRUE, meaning the HERMA 500 IE and the PLC are successfully communicating.