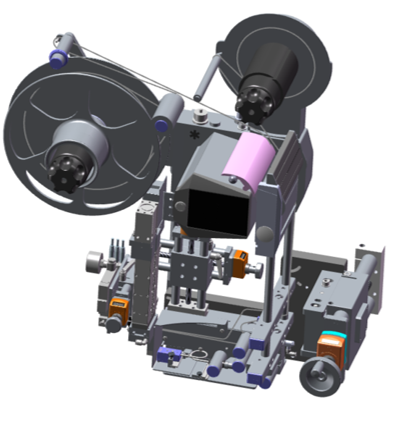

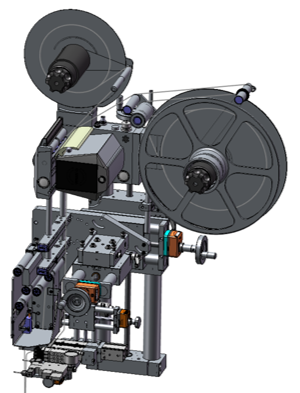

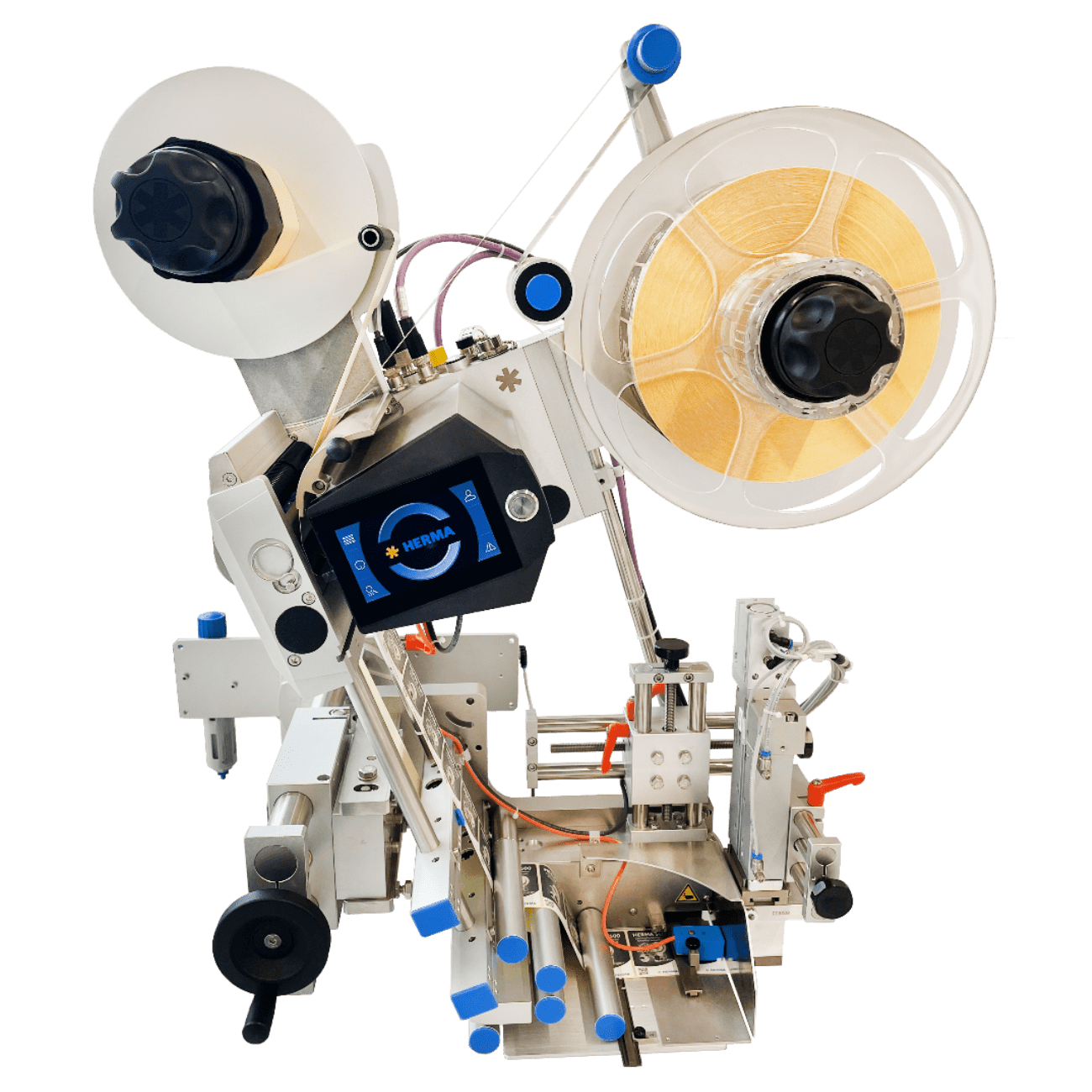

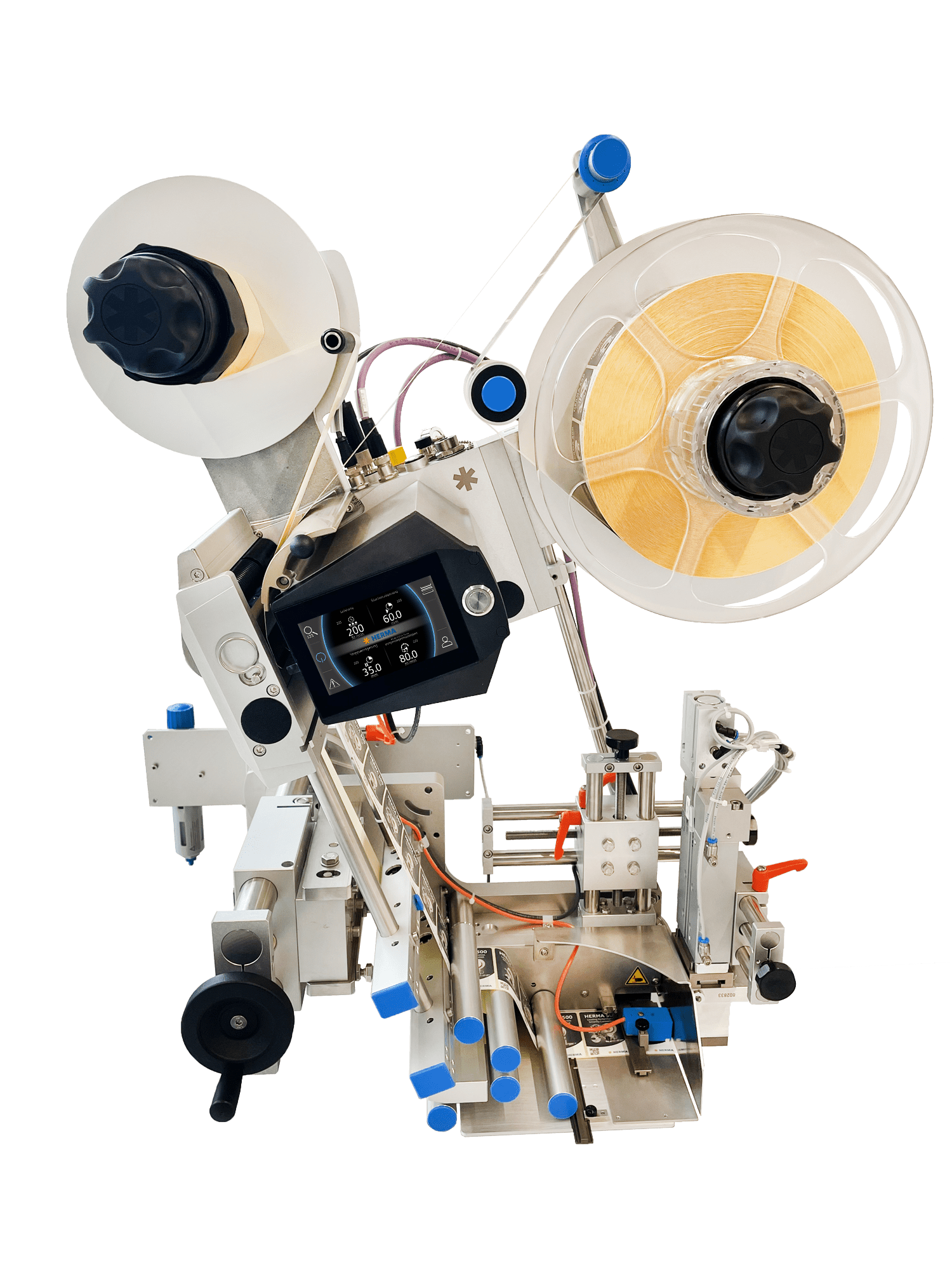

HERMA 500 MB

Applicator

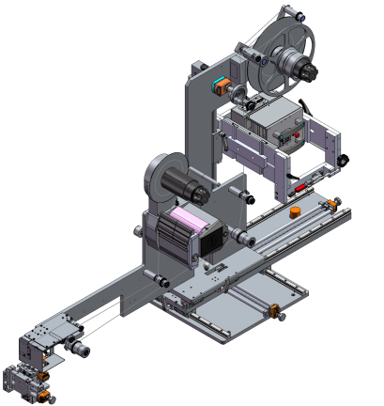

HERMA 500 MB with movable peel plate

Precision and fast cycle times

- Ideal for precise labeling of cosmetic products with decorative labels

- High-precision application of functional labels and self-adhesive functional elements, such as pressure compensation elements, membranes and RFID labels

- Compact design for easy integration into production lines - perfectly suitable for OEMs

- High-performance applicator HERMA 500 with integrated control and convenient adjustment of all parameters via the integrated touchscreen

- No additional control system required, integration into a higher-level machine control system on request

- On request, different printers can be integrated to print variable data

Integrable labeling system, versatile in use for top/side/bottom labeling

For many applications, absolutely precise labeling along with high repeatability is crucial. This is particularly important for technical and safety-related aspects. Electronic components with functional labels are only one example for it. But visual reasons also play an important role, such as decorative labels for fast-moving consumer goods.

For these and other applications, the HERMA 500 MB ensures maximum precision in label transfer. And combines it with an overall very compact design for flexible integration into indexing production lines. Typical applications are the separation of complex labels or the application of self-adhesive functional labels, such as membranes, RFID labels or self-adhesive seals and foams.

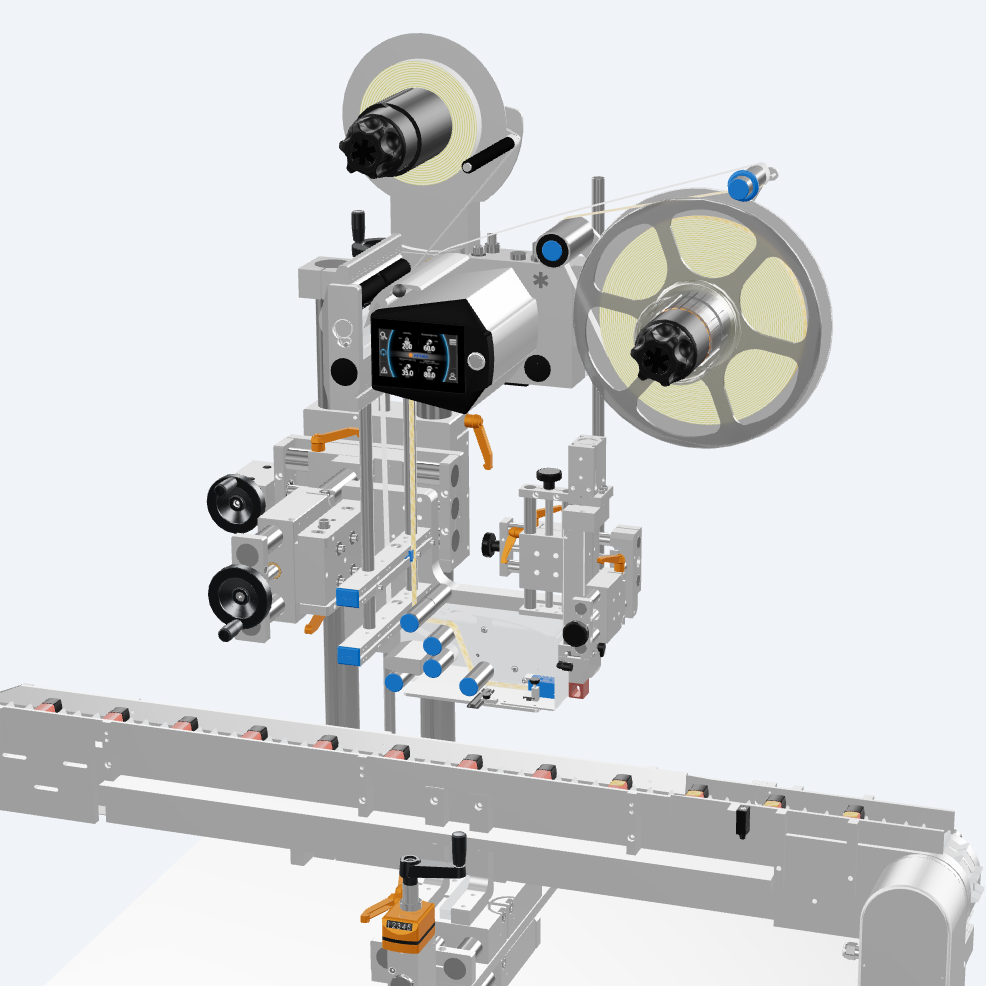

Discover the HERMA 500 MB as a 3D model

- Click on the blue button to load the HERMA 500 MB model.

- Click and drag with the mouse to move the HERMA 500 MB model.

- Scroll with the mouse to zoom.

HERMA 500 MB range – standardized to customized special solutions

HERMA All-in-one solution

- HERMA 500

- Label supply by the moving peel plate

- Label application via transfer unit and tamp pad

- Control completely integrated in the HERMA 500

- Convenient and intuitive operation via touchscreen

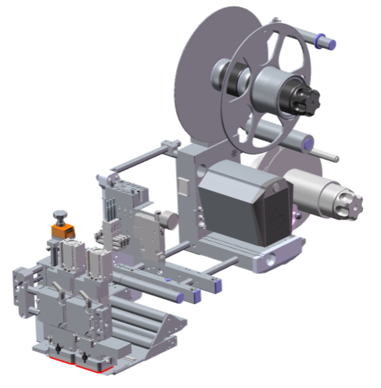

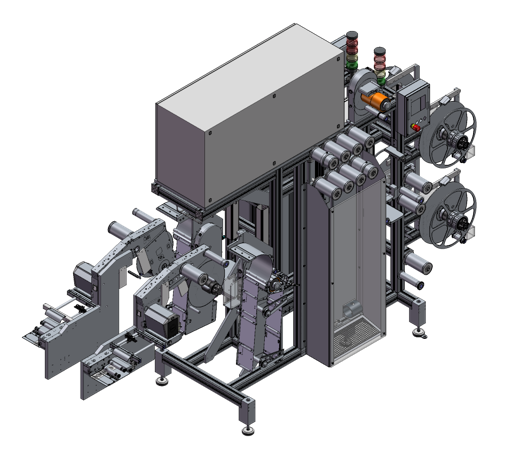

HERMA special solutions

- HERMA 500

- Label supply by the moving peel plate

- If required, without transfer unit and tamp pad

- Label application via OEM solutions, e.g with robots picking up the labels and placing them onto the products

- If required, communication interfaces like Profinet, Ethernet/IP or Modbus to integrate the HERMA 500 MB into a higher-level control (PLC)

- Integration of printers for variable data printing

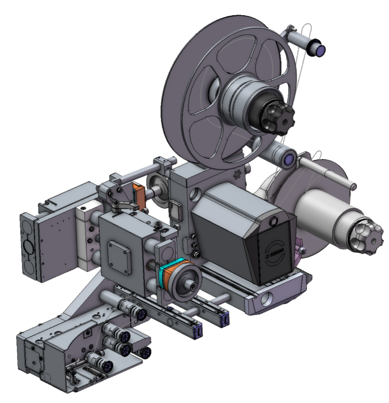

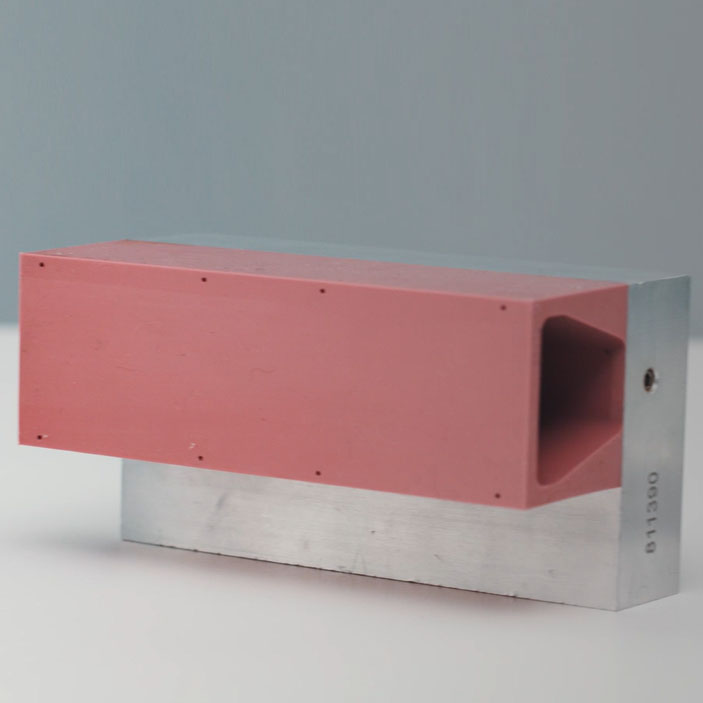

Tamp pad individually tailored to label and respective product

And this is how it works

Separated and centered, the products are fed to the HERMA 500 MB. After the labeling start, the movable peel plate transports the label under the tamp pad of the transfer unit. The label on the tamp pad is then applied to the product by the transfer unit and with high precision and repeatability. This guarantees optimum results both on products with flat surfaces and on surfaces with raised or recessed areas. Even at up to 70 products per minute.

Start, movement of movable peel plate

After triggering the label start signal, the moving peel plate moves pneumatically below the transfer unit with the tamp pad.

Label transport

At the same time, the label transport starts.

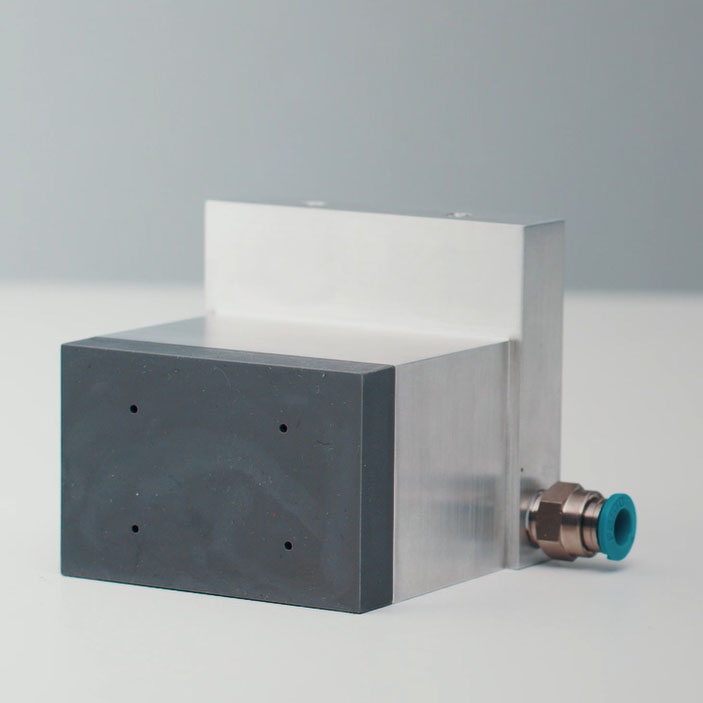

Transfer of the label to the tamp pad

By activating the vacuum, the label is sucked to the tamp pad.

Transfer of the label to the product

The sucked label is applied to the product by the linear transfer unit.

Peel plate in home position

The peel plate moves back to the home position.

Final adhesion to the product

After the label application the linear transfer unit moves back into the home position.

HERMA 500 MB for precise labeling of various products

The efficiency and profitability of entire production lines depend on reliable and, above all, precise labeling in high frequency. Our labeling solution with a movable peel plate masters these requirements even under the most difficult conditions. Regardless of whether you work in the cosmetics, pharmaceutical, automotive, food or consumer goods industries, the HERMA 500 MB labels precisely and reliably in order to meet optical, but also safety-relevant aspects.

Here are a few applications that have already been successfully labeled with the HERMA 500 MB:

- Wheels

- Batteries

- Button cells

- Cups

- Aluminum tubes

- Blister packs

- Caps

- Diagnostic tubes

- Plastic bottles

- Battery cell cans

- Folded cartons

- Paint bucket

- Shaped bottles

- Glass tiles

- Inhaler

- Insulin pen

- Antennas

- Screw drivers

- Carton

- Cartridges

- Cosmetic pens

- Rubber parts

- Packed food

- Steering hubs

- Lip stick

- Metal plates

- Nail polish

- Perfume Boxes

- Tubular bags

- Electronic components

- Chocolate figures

- Beverages

- Window wiper

- Pen

- Mascara

- Thermoformed packaging

- Cosmetic tins

- Tobacco products

- ...

- and much more!

Technical data

|

Labeling type: |

Top/side/bottom labeling |

|

Product specifications: |

Rectangular, oval, cylindrical, largely stable in form |

|

Product dimensions: |

No limitations |

|

Label dimensions: |

15 - 160 x 10 - 100 mm (W x L) |

|

Labeling tolerance: |

Up to 0.2 mm |

|

Capacity: |

Up to 70 products/minute |

|

Power supply: |

100 - 240 V AC, 400 W, 50 - 60 Hz |

|

Compressed air supply: |

6 bar |

|

Printer: |

Various hot-foil and thermal transfer printers (optional) |

|

Components: |

Attachment holder, applicator with movable peel plate, linear transfer unit with attachment holder for tamp pad |

|

Options: |

Label web stopper, pick-up cylinder, tamp pad adapted to label and product, digital position indicator, interfaces for integration into higher-level control |

|

Note: |

If optional features are chosen, the above data may vary. |

Contact

Request for quotation

We produce labeling solutions according to your specifications - suitable for your application!

![[Translate to English:] HERMA Formular Etikettiermaschinen Angebot anfordern](/fileadmin/Etikettierer/kacheln/HERMA_Formular_Etikettiermaschinen_Angebot_anfordern.jpg)

Please take a moment to provide us with some detailed information about your labeling solution requirements on the following page so that we can give you a good consultation.

![[Translate to English:] HERMA 500 Etikettenübergabe mit Abholzylinder](/fileadmin/Etikettierer/Produkte/HERMA500/HERMA_500_MB/HERMA_500_Etikettenuebergabe_mit_Abholzylinder.gif)