Requirements for the print data for roll labels in digital printing

To ensure that your order runs as smoothly as possible, we ask you to observe the following print data guidelines. Graphic programmes such as Adobe Illustrator, InDesign or ArtPro are suitable for creating professional print data that meets our requirements.

Print data upload during the ordering process

Please upload your print data per type (print motif) in the order overview of the Label Configurator.

We will check your print data after the order and contact you if there are any errors.

Checklist for correct print data

Please follow the instructions in this checklist so that we can fulfil your order as requested.

Important key data

File format: PDF (high-resolution)

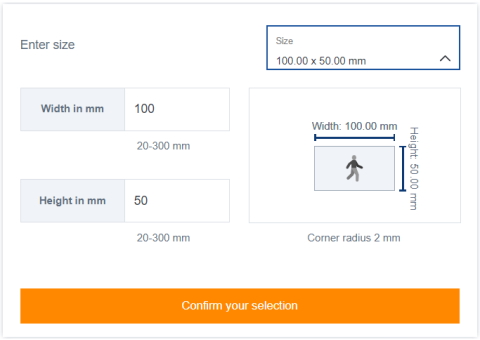

Create print data in original size (1:1)

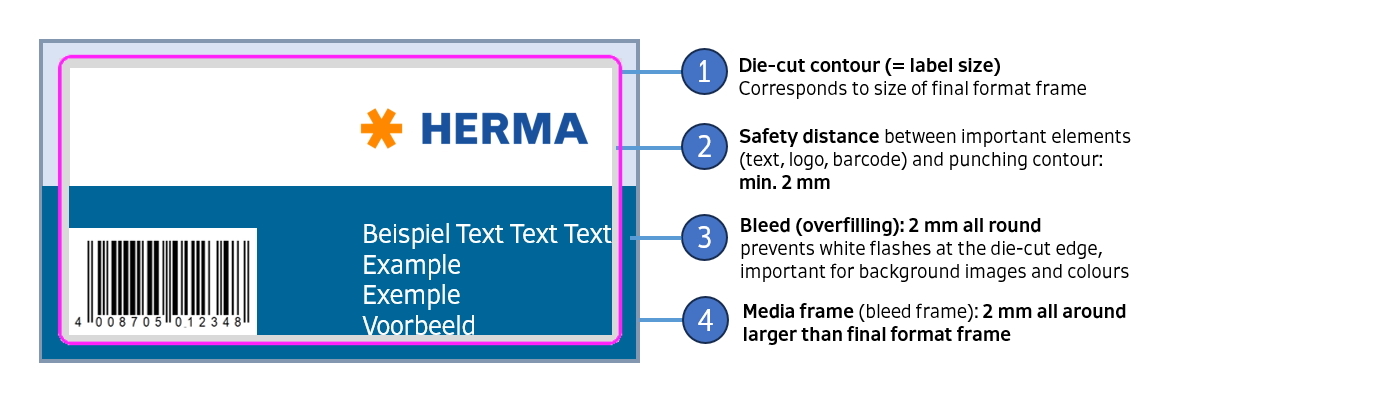

Data created in final format (= label size)

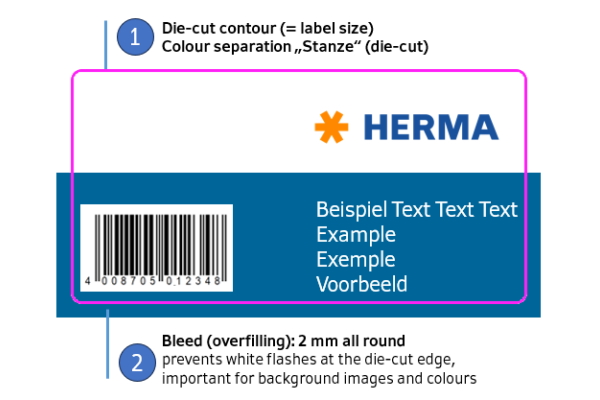

Bleed: 2 mm all around

Safety margin indside: 2 mm

Create die-cut contour as separation

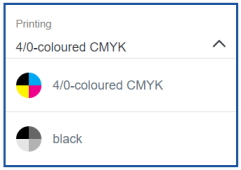

Colour composition: CMYK

Note opaque white for transparent labels

Standard resolution for images: 300 dpi (CMYK, embedded)

Fonts converted to paths

Maximum file size for data upload when ordering: 10 MB per print file (type)

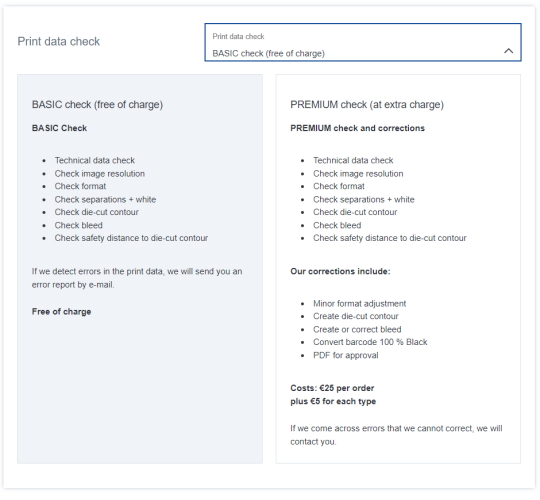

Print data check

In the label configurator, you can choose the extent to which we check your data and adapt it if necessary (where technically possible).

The BASIC check is free of charge for you. If we find any errors in the print data, we will send you an error report by e-mail.

Beim PREMIUM Check berechnen wir 25 € pro Auftrag, plus 5 € für jede Sorte (Druckmotiv).

This includes the corrections by HERMA listed below. You will receive a PDF for print approval. If we find any errors that we cannot correct, we will contact you.

Please note that the corrections relate only to suitability for printing, not to spelling mistakes or errors in content.

BASIC Check

- Technical data check

- Check image resolution

- Check format

- Check separations + white

- Check die-cut contour

- Check bleed

- Check safety distance to die-cut contour

If we detect errors in the print data, we will send you an error report by e-mail.

Free of charge

PREMIUM Check and corrections

- Technical data check

- Check image resolution

- Check format

- Check separations + white

- Check die-cut contour

- Check bleed

- Check safety distance to die-cut contour

Our corrections include:

- Minor format adjustment

- Create die-cut contour

- Create or correct bleed

- Convert barcode 100 % Black

- PDF for approval

Costs: €25 per order plus €5 for each type (print motif)

If we come across errors that we cannot correct, we will contact you.

Checklist for correct print data

Please check your print data - if everything is correct, upload your print data PDF in the order overview in the label configurator (one print file per type).

Order customised printed roll labels now.

You can customise and order roll labels in digital printing online here.

In your desired format. Short delivery time. Attractive price.