Transport labels that have no liner whatsoever - Linerless labels reduce waste and costs and protect the environment

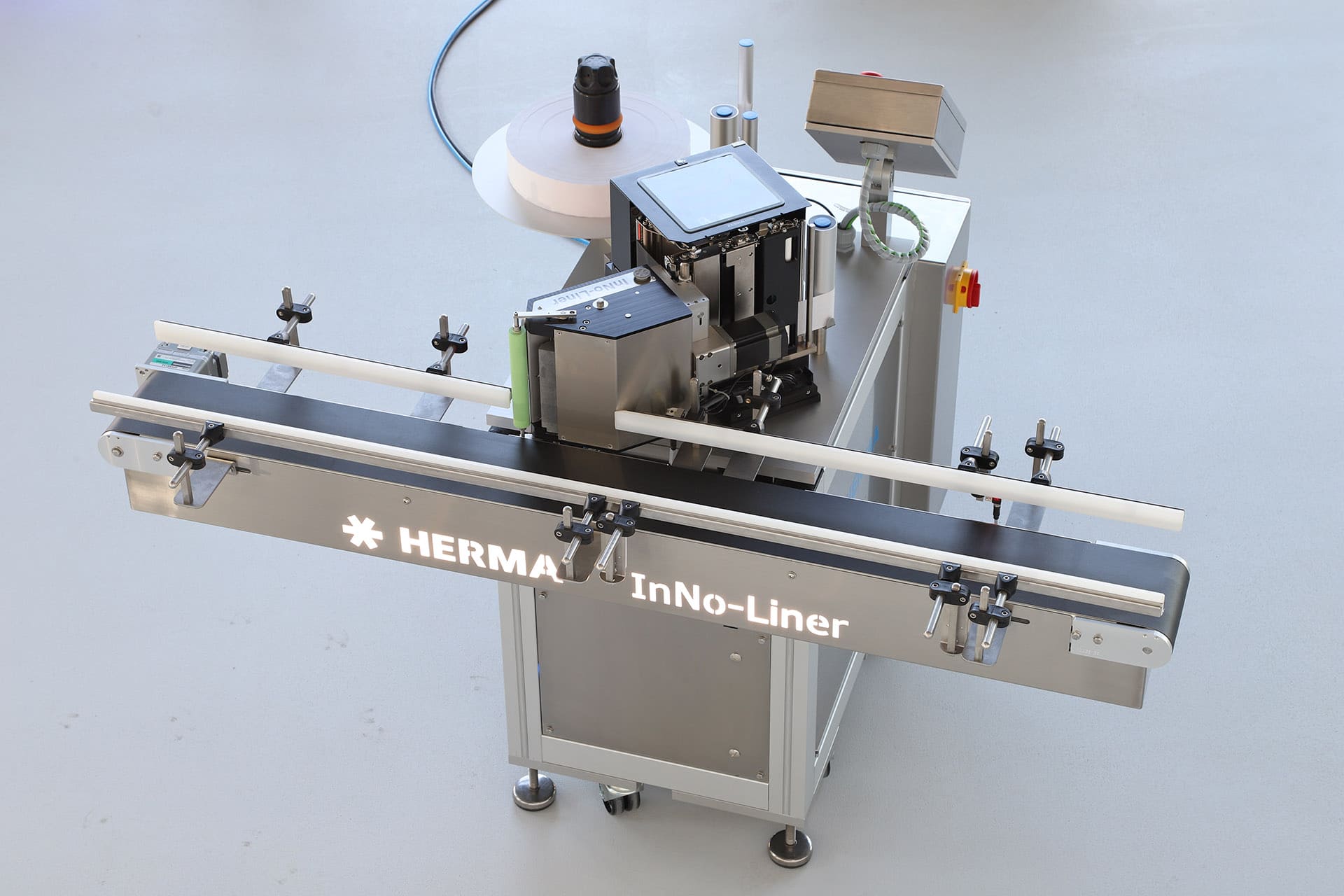

Almost all packages have a large transport label. Thanks to the new HERMA InNo-Liner system, thousands of tons of backing (liner) material and their costly disposal can be saved every year. The patented, initially non-adhesive linerless label is activated with water when dispensed, and then adheres strongly to the shipping cartons. The entire, climate-relevant CO2 footprint of a linerless label is drastically reduced.

Economic advantages

- Saving of disposal costs

- Reduced label price

- Lower transport costs

- Less space required for storage

Ecological benefits

- No backing paper material waste

- CO2 reduction

- Free from silicone

- Water-based activation

Application benefits

- Different label lengths

- Secure final adhesion

- Fewer roll changes

- Reduced downtimes

Ready for the future - with HERMA linerless labels

The HERMA InNo-Liner system is a forward-looking solution, especially when you consider how the global volume of parcels is going to develop. Experts predict that the number of cartons transported will have almost doubled by 2025 – to around 200 billion worldwide.

DHL relies on InNo-Liner solution from cab and HERMA

DHL: ‘This allows us to reduce waste by around 60 per cent, and it is around 40 per cent cheaper than conventional labelling systems.’ Read more in the latest news Play video

NEW: Now also for

cab Print&Apply systems!

Curious? Read more

What are the differences between the new linerless labels and conventional self-adhesive labels?

The decisive difference is: Linerless labels in HERMA InNo-Liner Technology have NO backing paper. Conventional self-adhesive labels sit on a siliconized backing paper, and are already self-adhesive when they are detached from the underlay paper or the roll labels are dispensed by machine via a conventional labeling unit.

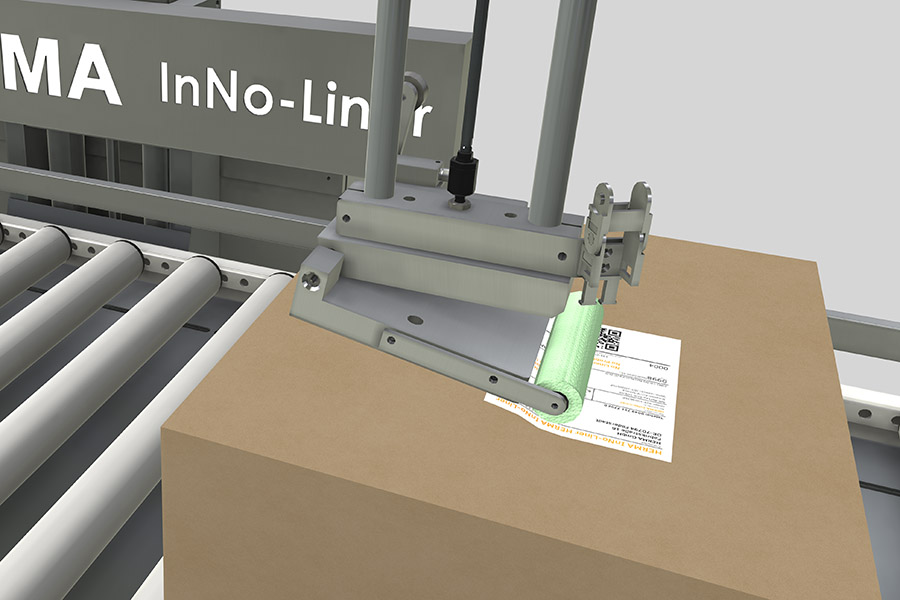

With the linerless labels from the HERMA InNo-Liner system, the label materials are also wound on roll, but they are not sticky because the adhesive is initially deactivated. Therefore, no siliconized backing paper is required. Only when labelling, a precise, purely water-based activation by the micro-atomization unit ensures that the linerless label becomes sticky and adheres – thanks to multi-layer technology for the adhesive immediately evenly and firmly on the surface. This requires a dispensing unit, which HERMA naturally offers in the InNo-Liner system.

HERMA InNo-Liner labels can also be printed, activated and dispensed with Print&Apply systems from other manufacturers.

Find out more about the cooperation with our partner cab

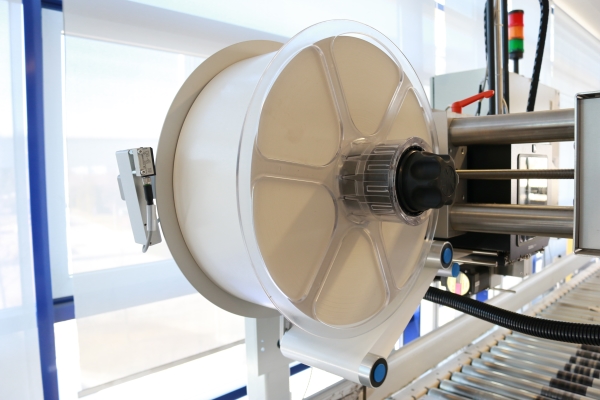

The width of the linerless labels on roll is determined by the width of the material. The label length is variable, and is defined by a cutting unit when labelling. Due to the lack of backing material, more labels fit on a roll, which in turn is easier to transport and takes up less space in the warehouse.

Linerless labels HERMA InNo-Liner: ideal for shipping labels

A transport box without a shipping label - unimaginable. This is because shipping labels ensure that the parcel reaches the right recipient safely.

131 billion parcels per year: This value is given by the "Parcel Shipping Index" for 2020 – for 13 major "shipping nations" such as Germany, England, France, Italy, the USA, China and Japan alone. In Germany alone, more than 13 million logistics labels are used on transport cartons every day (source: Bundesverband Paket und Expresslogistik (BIEK)).

Considerable figures - and considerable savings potential with HERMA InNo-Liner labels, which, in conjunction with the HERMA InNo-Liner labelling system or the cab HERMES QL labelling system, meet the cycle rates and requirements of shipping and logistics centres.

Extremely important for shipping labels is the secure adhesion to the often rough and dusty cardboard surfaces. The multi-layer technology of the adhesive ensures that the linerless labels adhere securely and firmly immediately after labelling - permanently!

Linerless labels now also for the labelling of variable carton heights

The linerless HERMA InNo-Liner system can now also label variably-fed transport cartons, i.e. cartons of different sizes, in any order, either on the side or on the top of the carton, with linerless labels. The non-adhesive linerless label with the inactive adhesive is transferred to a vacuum suction plate, which is equipped with a linear unit and a sensor to determine the carton height. The water-based activation unit then activates the adhesive with a micro-fine, extremely even spray mist. The linear unit then automatically moves the vacuum suction plate with the activated linerless label to the labelling height required for that particular package, with the adhesive side facing the cardboard.

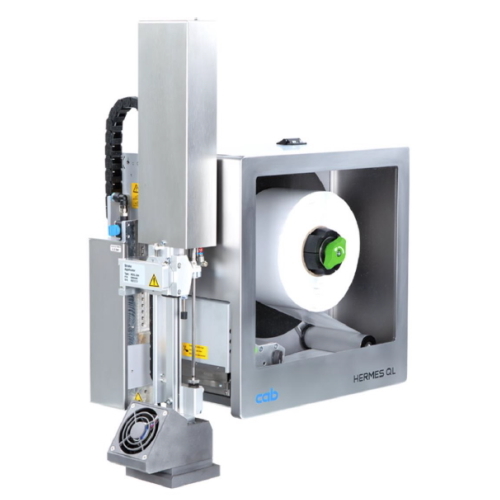

NEW: Cooperation cab and HERMA

HERMA InNo-Liner labels can now also be printed and dispensed with the cab HERMES QL labelling system

cab, one of the leading manufacturers of label printers and labelling systems, now offers the possibility to print and apply HERMA InNo-Liner labels with the new HERMES QL labelling system. With an interesting price/performance ratio, compact design and short delivery time.

The new cab HERMES QL linerless printing and labelling system processes HERMA InNo-Liner labels using direct thermal printing. On request, the system can also be provided for HERMA InNoLiner themotransfer labels.

Our partner cab will be happy to advise you on which Print&Apply system from the HERMES QL series is right for your application!

Read more about the cab HERMES QL with HERMA InNo-Liner / Contact cab

Saving material without generating additional costs?

Read more in the interview with Clement Kleinclauss, Managing Director of cab in France.

DHL adopts InNo-Liner solution from cab and HERMA

Shipping labels without liner material or silicone coating offer a sustainability advantage that has also convinced a leading logistics provider like DHL. At its site in Nohra, Thuringia, Germany, the company has now switched from conventional self-adhesive labels to a joint InNo-Liner solution from cab and HERMA.

“It enables us to reduce waste by roughly 60 percent, simply because the silicone-coated liner is eliminated and we gain flexibility in label sizes,” says Aiste Slabokaite Heid, Business Unit Director North-East DHL Supply Chain Germany & Alps. “The system also helps us cut costs: It is about 40 percent more economical than conventional labeling systems.”

Linerless labels: more cost-effective than a conventional self-adhesive shipping label

The HERMA InNo-Liner system easily manages the usually required cycles for labelling shipping cartons. And the costs for the linerless labels are lower than for a conventional self-adhesive label. The decisive advantage of the linerless label without liner: the costs for disposing of the liner or backing material are eliminated completely. Plus: the elimination of the backing paper reduces the storage costs for the labels, because there are about 50% more labels on the roll for the same roll size.

CO2 savings with HERMA Linerless labels

With an annual volume of 2 million shipping labels in the common format 105x148 mm (A6), the use of conventional self-adhesive labels results in a carrier paper area of approx. 32,700 m², which corresponds to an area of more than 4 foot panels. The weight of the carrier material is about 1.8 tons. When using linerless labels, this carrier material is completely omitted.

By eliminating the carrier paper, the CO2 footprint is reduced by 1.89 tons of CO2. This already means 45% less CO2 emissions compared to the classic self-adhesive label.

Further CO2 savings are achieved by eliminating matrix waste in the production of classic self-adhesive labels. This results in a further CO2 saving of approx. 12% (with roll width 333 mm). Due to lower warehousing and handling costs, further savings of approx. 3 percent can be achieved. Together, this is about 60% total CO2 savings with the HERMA InNo-Liner system - compared to a classic self-adhesive label.

In this example, the savings in the disposal of the carrier paper are about 180 euros per year. Based on 1000 labels, this is 0.09 Euro/1000.

Calculator for determining the CO2 savings with HERMA InNo-Liner

Quickly and easily determine your possible CO2 savings if you rely on linerless labels without carrier material instead of self-adhesive labels with carrier material.

Linerless labels with HERMA InNo-Liner technology - how do the variable data get on the label?

The linerless labels are wrapped "on themselves" on roll. Due to the deactivated adhesive, they do not stick to themselves - no silicone is needed on the label surface to prevent sticking - a great advantage over other linerless systems.

This makes it possible for HERMA InNo-Liner label rolls to be pre-printed in one or more colours in conventional printing processes at HERMA, for example with your company logo in in-house colours or shipping instructions, which should be particularly striking.

Only when the linerless labels are dispensed with a HERMA InNo-Liner dispenser or the cab HERMES QL labelling system does a precise, purely water-based activation ensure that the HERMA linerless label becomes tacky. The adhesive with multi-layer technology ensures uniform and immediately very strong adhesion to the surface.

Linerless labels are printed directly with the variable data in the HERMA labeling unit before they are self-adhesive activated and dispensed (Print&Apply). You can choose between thermal transfer printing and direct thermal printing. The HERMA InNo-Liner system is also comparable to other Print&Apply systems in terms of printing and dispensing speed.

The cab HERMES QL linerless printing and labelling system uses HERMA InNo-Liner linerless labels in a Thermo eco quality. This linerless label quality is suitable for use in the dispatch area and can be printed at high speeds. The thermal linerless labels are also approved for use in the food sector.

We produce your HERMA InNo-Liner label rolls with the appropriate label paper to match the linerless label printer system. This results in shipping labels of the best quality, directly in the logistics process.

The following linerless label materials are currently available:

For thermal transfer printing:

- Paper, white, satined

For thermal direct printing:

- Thermal paper ECO, BPA-free, white (without protective coating)

All HERMA linerless labels can be pre-printed in several colours, e.g. with your company logo.

Learn more about the components and the complete solution HERMA InNo-Liner

With a unique, end-to-end chain of know-how: from adhesive material to labels to high-performance labellers, all three business units have jointly developed the InNo-Liner system - with full commitment to innovation and sustainability in packaging and logistics processes.

Learn more about the technical details of the adhesive material and Print&Apply system - and contact us - we will be happy to advise you and work with you to develop the optimal solution for your specific application.

Please use this contact form for inquiries about industrial requirements.

If you have any questions about HERMA branded products in smaller packaging units, we look forward to your inquiry using the contact form "Office and Home".

Request a quotation

We produce labels according to your specifications - to suit your industrial application!

Please take a moment to give us some detailed information on the following page so that we can advise you well.

Self-adhesive shipping labels - ideal for all surfaces

For many surfaces in the logistics sector, classic self-adhesive labels are the optimal solution, e.g.

- Transport labels on shrunken pallets (stretch films)

- Shipping labels on uneven surfaces (e.B. containers)

- Pallet foot labels (rough wood surface)

- and of course also for shipping boxes that are labeled with other systems

Learn more about HERMA transport labels and pallet labels