Thermal transfer labels – universally applicable and particularly durable

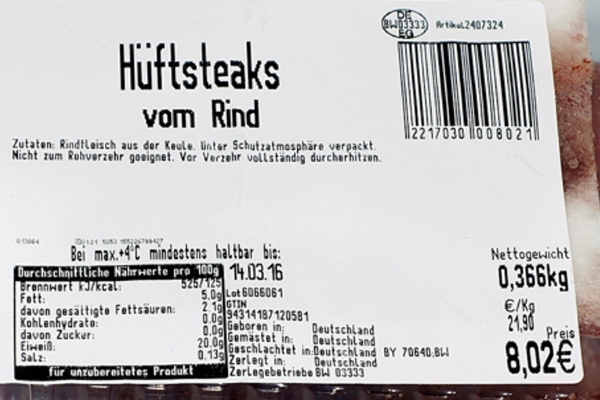

Thermal transfer printer labels are the first choice for durable labelling. Product labels with barcodes, date of manufacture, date of filling, sell-by date and content labels on outer cartons are just a few examples of how thermal transfer printer labels on rolls can be used.

Adhesive labels are printed using a thermal transfer ribbon during the thermal transfer printing process. A thermal transfer label does not have a special printing layer – a printing head in the printer heats the colour ribbon at the points that are to produce the print image. The coloured printing ink is “melted” onto the label by transferring the thermal transfer film particles onto the label material. The advantage of this process is that the print on the labels remains legible for a very long time. Thermal transfer label printing is carried out in monochrome, in the colour of the transfer ribbon (usually black). However, thermal transfer ribbons are also available in other colours. The temperature that is pre-set in the printer is decisive for a successful print image: Temperatures that are too low are not sufficient to transfer the inks, whereas excessive heat can adversely affect the printouts.

To produce high-quality printouts, the interaction of the thermal transfer printer, the coloured ribbon and the material of the thermal transfer rolls must function perfectly. Our many years of experience in this field enable us to recommend the right combination of adhesive labels and thermal transfer film that perfectly matches your thermal transfer printer.

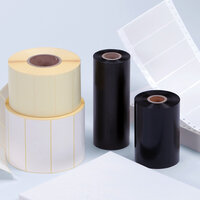

Thermal transfer ribbons matching your needs for the perfect thermal transfer label

Thermal transfer ribbons (also called TT ribbons, transfer films) are available in various qualities. A distinction is made between wax, wax/resin blended and resin ribbons. The ribbon types have different pigment densities, durability levels and smudge & scratch resistance levels. Different ribbon types are used, depending on the label material and the usage scenario. For example, high-quality ribbons made of resin or a blend of resin and wax are used for thermal transfer labels made of film, ensuring that the print is securely fused and anchored to the label. Resin ribbons are also used in thermal transfer labelling when resistance to alkalis and acids is necessary, e.g. for nameplates. The label material and the transfer ribbon must interact perfectly to obtain a smudge-proof and scratch-resistant printout.

We are one of the leading specialists in self-adhesive technology – and we can offer you everything from a single source. Thermal transfer label rolls plus ribbons that match the labels – and if required, we’ll supply you with the right labelling machine as well. Thermal transfer labelling from a single source.

Experience the powerful features of our thermal transfer labels

Best possible adhesion on a wide range of surfaces

HERMA thermal transfer printer labels can be used universally on many different surfaces. Their wide temperature range (-30° to + 80°), strong initial adhesion, and very powerful final adhesion ensure that the labels stick to even rough cartons and smooth packaging films – securely and durably.

Mature roll technology for trouble-free processing

In addition to reliable printability, trouble-free processing also plays a vital role in the printing and application of thermal transfer labels. Our label material features strong adhesion to the backing and excellent labelling properties in packaging plants, even at high labelling speeds – and it is this all-round reliability that prevents malfunctions and the resulting downtimes.

What are thermal transfer labels used for?

The thermal transfer label rolls are suitable for industrial thermal transfer printers from well-known manufacturers, such as Zebra, Sato, cab, TSC und Datamax. These label printers are used in all the industry sectors, including manufacturing, production, logistics and retail. Thermal transfer labels are suitable for printing smaller batches of labels and for continuous operation in production. In large quantities, thermal transfer printer labels are also used for labelling transport & shipping containers.

Thermal transfer printer labels are ideal for attaching to packaging made of paper, cardboard and film, to bottles, cans and glass jars, and for use as classic address or inventory labels. Thermal transfer labels are used to label food, equipment and other products such as components, devices and machines.The locating of industrial printers close to the production area enables the subsequent imprinting of barcodes, sell-by dates and other manufacturing information on the thermal transfer label, timed to coincide with the manufacture of the products.

How can thermal transfer labels be applied safely?

HERMA labelling machines are perfect for attaching thermaltransfer labels on rolls to various surfaces. An integrated printing solution for thermal transfer label rolls can also be supplied on request.

What are the advantages of thermal transfer labels?

- Long service life due to high durability of the imprint - for reliable and legible marking

- Versatility – reliable adherence to a wide range of different surfaces

- Easy handling – the labels can be attached either manually or by machine

- Consistent print quality – secure anchoring of the coloured ink particles on the label material

- Brilliant and contour-sharp print with high contrast - for the best possible barcode readability

- Individual pre-printing, e.g. with company logo and constant information, and flexible reprinting via thermal transfer printer possible

- Reprint barcodes, filling data & BBD - in the desired quantity, directly in production

- Availability and flexible choice of materials: available in many formats and materials (papers, foils)

- Relatively inexpensive compared to inkjet and laser printing

Discover practical uses for HERMA thermal transfer labels on rolls

If labels are to be printed in production or logistics and dispensed with a labelling unit, thermal transfer printers on a roll are the ideal solution. We produce thermal transfer labels on rolls according to your specifications, and common standard formats are available immediately from our online shop. In the ‘Solutions’ section, you will find many practical examples of the use of thermal transfer labels on rolls for a wide range of industries and requirements.

For rough recycling cartons in online mail-order transport: Shipping labels for recycling boxes

Reliable adhesion and removability on steel mesh pallets and polystyrene trays: Container labelling

Labels for rough grey cardboard boxes as packaging labels

Parcel labels compatible for DHL and other shipping service providers

Traceability with batch labelling in the food industry

Labelling food on a daily basis with take-away labels

For beverage crates and pallets: labels for the beverage industry

Batch tracing of trading goods

Labels in the DIY store for individual colour mixing

Product and price labelling with labels in DIY stores

Traceability in the automotive industries and railway industries

HERMA thermal transfer labels are available in many standard formats in our online store:

Thermal transfer labels in standard formats

The high-quality label paper is white and the adhesive is permanent. These labels are suitable for direct contact with dry and non-fatty foodstuffs. The standard thermal transfer labels on rolls have a roll core diameter of 76.2 mm - or in special cases 152 mm.

Or in customized production - thermal transfer labels with format and material as desired.

Thermal transfer labels in custom production

We will produce thermal transfer labels in your desired format and label material. Paper and film labels, with permanent or special adhesive features (e.x. extra-strong adhesion, removable or suitable for frozen storage), from our in-house label material production facility. Special stampings and perforations enable us to create unique solutions for your usage scenario. We’ll be happy to provide you with an individual offer for your thermal transfer rolls. Use our enquiry form to get in touch with us fast.

Request a quotation

We produce labels according to your specifications - to suit your application!

Please take a moment to give us some detailed information on the following page so that we can advise you well.

Frequently asked questions about thermal transfer labels

What is a thermal transfer label?

Thermal transfer labels are special labels for thermal transfer printing.

The thermal transfer printing process requires a thermal transfer ribbon that is heated at the desired points during printing. This transfers colour particles from the ribbon to the label (hence the name "transfer"), where they produce the corresponding imprint. This print lasts much longer and produces better printing results (brilliant and sharp contours) than a direct thermal print.

Most applications with roll labels are based on thermal transfer printing labels. The print image is consistently good and permanently legible, as the print is applied by heating (melting it, so to speak).

Thermal transfer labels are available in many different material combinations of different label papers and films, with different adhesives. Any label size and shape is possible. The optimal combination of label material, liner and adhesive guarantees long-term fulfilment of the requirements for the respective application.

Which printers can be used for thermal transfer labels?

Thermal transfer labels on rolls can be printed with all common thermal transfer printers (industrial printers).

It is important that the specific requirements of the printer, such as sleeve diameter, maximum ribbon width and maximum roll diameter, are taken into account.

What are the advantages of thermal transfer labels?

Thermal transfer labels on rolls can be applied by machine. This has great advantages when labelling packaging, cartons and pallets in large quantities in production and logistics.

The important thing here is trouble-free processing when printing and dispensing the labels. If just one label causes a malfunction, packaging lines or shipping lanes can come to a standstill.

Thermal transfer labels on rolls, made of high-quality label materials, with optimum dispensing properties, and pressure-sensitive adhesives with high initial and secure final adhesion ensure processing reliability, even at high dispensing speeds.

What are thermal transfer labels used for?

Thermal transfer labels are suitable for many applications and uses. Due to the high variety of materials, almost everything is possible, from simple shipping labels to chemical-resistant labels. A thermal transfer label is the best solution when the imprint needs to be permanently legible, for example: Labels for shipping and transport labelling, product labelling on packaging of all kinds, food labelling, e.g. with current production data (best before date, filling quantity, lot number), inventory labels on furniture, machines and echnical equipment as well as rating plates on equipment and machines.

What is the difference between a direct thermal and a thermal transfer label?

Thermal transfer printing uses conventional label materials made of paper or film that do not have a special thermosensitive layer. In contrast to the direct thermal printing process, an ink ribbon is used in these printers, the ink particles of which are transferred (transferred) to the label paper in the printing head (heating element) under the influence of heat, hence the name "thermal transfer". The print is durable and does not fade. The interaction between the thermal transfer printer, the ribbon and the label material is crucial for high-quality prints.

Direct thermal printing requires special paper that is heated directly in the thermal printer and turns black in the areas to be printed due to a chemical reaction (heat-sensitive paper). No ink ribbons are needed. The print is sensitive to UV radiation and can fade.

Thermal transfer labels are not what you were looking for?

Discover roll labels for other printing systems:

Labels for inkjet roll printers, for multicolour printing

If you want to have multicolour printing on your labels on rolls, we recommend using a colour inkjet printer (for efficient roll processing) and the matching HERMA blank inkjet labels on roll for colour inkjet roll printers

Labels for direct thermal printer

In contrast to the thermal transfer printing process, direct thermal printing uses a special paper that is heated in the thermal printer. A chemical reaction (in the thermally sensitive paper) then turns the paper black at the points to be printed. No coloured ribbons are required. The print on the labels is sensitive to UV radiation and may fade with time. Direct thermal printing is used in fruit scales, for instance – but address, shipping, carton and pallet labels can also be created with HERMA thermal labels on rolls.