Optimise labelling - 7 opportunities for process improvement and cost reduction!

Product labelling in compliance with all guidelines can be quite complicated. Best-before date, barcodes, content information and much more that has to be placed on a product label. Logistics labels are indispensable for reaching the recipient quickly and safely. The labelling options are numerous. The aspect of sustainability is also becoming increasingly important.

It is therefore all the more important to optimise the work processes and the material in the best possible way. Optimised labelling and economical labels mark your product quickly, safely and cost-effectively and accompany it reliably on its way to the consumer.

Label Consulting: Let's work together to make your production even more successful and economical!

-

Economical labelling with innovative materials

Often, for historical reasons, label materials are used that are no longer up-to-date and useful for your application. And new types of labelling systems offer interesting savings opportunities through process optimisation. We also have a lot to offer in terms of sustainability.

This is where our label consultancy comes in: because the entire process should always be considered in order to achieve optimised labelling and an economical solution.

Laser-activated labels

offer a high savings potential in the production process. The labels are marked by laser in a fraction of a second, directly in the packaging process. We offer everything from a single source: labels, plus CO2 laser, plus labelling unit or labelling machine. Learn more about laser-activated labelsHERMA InNo-Liner System:

Labels without backing paper sustainably reduce waste and CO2 emissions. And all in all they are cheaper than classic self-adhesive labels. We offer the complete system: Print&Apply unit with printing system and labeller plus the patented linerless label. Learn more about linerless labelsHERMA Thin Range labels

For logistics labels, the label material depends on the printing system used. Savings can be made here by using thinner adhesive materials. HERMA Thin Range offers thinner materials for roll labels: economical labels, with full functionality at the same time. Learn more about Thin Range labelsLabels are often an economical alternative to other types of labelling, e.g. as self-adhesive ratingplate labels on technical equipment instead of metal plates. In the case of full-colour printed information labels, a solid-colour label paper saves ink or toner during printing.

Is the right material used?

- Does the thick material quality make sense for the application?

- Is there a cheaper alternative to this material?

- Can other labelling systems be used?

Often, for historical reasons, label materials are used that are no longer up-to-date and useful for your application. Any oversized label material can be replaced with a cheaper material.

New types of labelling systems such as laser-activated labels offer interesting savings opportunities through process optimisation.

Linerless labels in the HERMA InNo-Liner system, without liner material, make an important contribution to sustainability.We are constantly working on label material optimisations and new types of labelling systems. And will be happy to advise you on economical labelling solutions!

-

What are your requirements for pre-printed labels?

Single colour black or multi-colour? Text only or image as well? Consecutive numbers or barcodes in defined number ranges?

Questions that have an impact on the printing system used for economical label printing in our production.Digital printing - ideal for high colour and variety diversity: In addition to traditional printing methods, we use the latest printing technology with the HP Indigo printing process. The print image is generated directly from the digital data.

This results in economical labels with above-average print quality and colour variety. Particularly suitable for product labels with a high variety of colours and types. Further savings can be achieved by bundling print jobs.

Barcode labels with consecutive numbering or serial numbers that require database-supported management can be ideally implemented in digital printing.

Learn more about barcode labels

Conventional or digital?

- What does the print look like?

- Do you need consecutive numbers or barcodes in defined number ranges?

- Can labels with different print images be produced together?

Using digital printing can reduce costs, especially for smaller quantities and changing layouts. Economical label printing can also be achieved in conventional printing processes: by combining layouts, the print run can be increased and the price reduced.

-

How are the labels printed with variable data?

Black or coloured? Text only or image as well? Short-term use or permanent labelling? Manual or automatic labelling? These are questions that have an impact on the printing system in your company, on economic label printing and, as a result, on the label material:

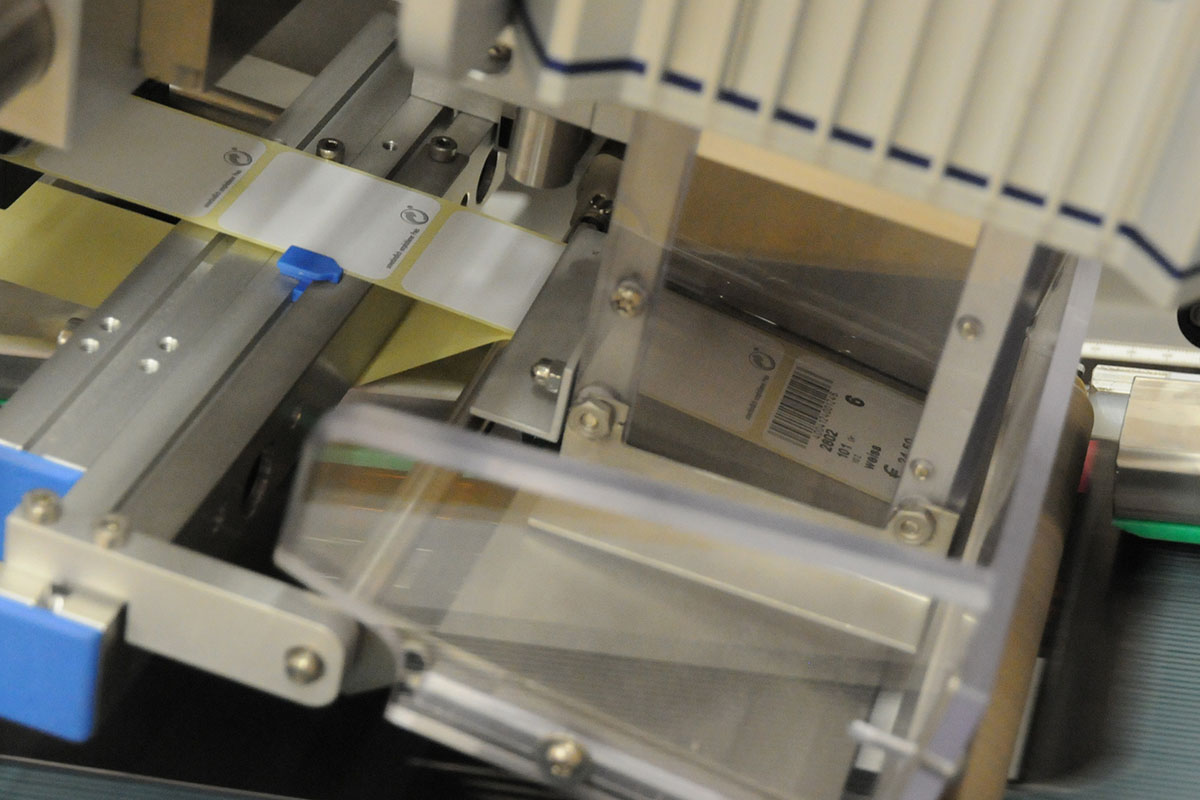

Variable data, such as best-before dates and lot numbers, are often printed in the packaging process and dispensed by machine. Roll labels are particularly suitable for this - made of different adhesive materials, depending on the printing system.

Direct thermal printing does not require ink ribbons, but the prints are not particularly durable. A special thermal label material is needed. Learn more about direct thermal labels on roll

Thermal transfer printing, in combination with a suitable TT ribbon, offers contour-sharp prints and high abrasion resistance - especially important for printing barcodes. Learn more about thermal transfer labels on roll

Laser-activated labels are printed and dispensed directly in the production process - in high cycle rates. Low maintenance and almost wear-free. We offer the complete solution: printing unit, dispensing unit and labels. Learn more about laser-activated labels

And linerless labels with the HERMA InNo-Liner system offer a particularly interesting Print&Apply solution from an economic point of view - while at the same time offering great savings potential thanks to the elimination of backing paper. Saves costs, protects the environment: Learn more about linerless labels

Laser printers and sheet labels are the first choice when colour printing and image durability are important. Learn more about labels on sheets for laser printers

Inkjet printers for roll labels offer great advantages when producing small series with changing print image, in brilliant colours. Learn more about inkjet roll labels for colour inkjet printers

Subsequent inscription

- What data do you print on the label?

- Are you using the optimum printing process?

- Can costs be reduced in the process by using innovative printing systems?

Costs can be saved by printing variable data on the labels at a later stage. Depending on the situation in your company, different systems can be used.

Our laser-activated labels and linerless labels in particular offer great savings opportunities in the process.

We will be happy to advise you!

-

How big does your label really need to be?

For logistics labels and other identification labels, it makes sense to adapt the size of the label to the imprint.

Labels for product identification are based on the intended area on the product. The amount of text is often large (especially for food labels). And often the product label is also a brand ambassador.

Too much white space around the information is for beauty, but not for economy.

Text should be legible, but not oversized. This also applies to images and graphics.

For barcodes, a white space of about 1 cm around the barcode is sufficient for it to be reliably readable with scanners and camera systems.

By reducing the label format (sometimes only one or two millimetres), the consumption of raw material can often be significantly reduced during production. This saving is of course also noticeable in the label price.

And: often your individual label format is only a short distance away from a HERMA stock type that can be ordered from our online shop.

At attractive conditions, available for immediate delivery. This saves money on labelling. -

Optimising the label orientation for roll labels

Is it important whether the label is arranged crosswise or upright on the backing paper? Or can width and height simply be exchanged?

With roll labels, the roll width is one of the decisive factors for material consumption in production. The optimised arrangement of the labels on the liner brings advantages: More labels can be produced next to each other - so more labels can be produced in less time - at lower costs.

Better utilisation of the original roll width of the labelstock brings further cost benefits. Width of the roll to match the width of the original roll leads to less waste - this is not only good for the environment, but also for your wallet.

By changing the label arrangement on the backing tape, the consumption of raw material can be reduced during production. And with that, significant savings are possible.

We attach great importance to the optimal utilisation of the labelstock, which, by the way, comes from our own production - from one of the most modern coating machines in the world.

-

Economical labels at special conditions

The same applies to labels: the larger the order quantity, the lower the price of the individual label. Often, requirements for several months can be bundled, especially for small label rolls that do not require much storage space. Shipping larger quantities of labels, e.g. in a pallet container, brings further savings opportunities.

For custom-made labels, which we produce especially for you, it is possible to arrange framework agreements/contracts with call-offs. By stocking raw materials from our own adhesive material production, we are able to produce quickly and flexibly.

Call-offs from these framework agreements are quickly delivered to you by internationally active forwarding agents - worldwide.

Significant savings can be achieved by bundling requirements. Making you an economical offer is our top priority.

-

Benefit from our range of stock goods

The desired format is not always the economically correct decision. Because often your desired format is only a few millimetres away from a standard format.

In our online shop we offer frequently requested standard formats at attractive conditions, immediately available from stock. This means you can cover your label requirements at short notice without having to keep a large stock of your own. And save money on labelling.

Find the product you want quickly and easily with the extensive filter options.

- Labels on A4 sheets in economical packaging of 100 or 500 sheets, in many different sizes.

- Labels on rolls for direct thermal printing or thermal transfer printing, in various formats and roll sizes.

- Labels on fanfolded liner, for matrix printers, with or without sprocket holes

Benefit from our label consulting!

When considering cost-effectiveness, always look at the complete system, not just the label price.

What deviates from the standard, we offer you custom-made, unprinted or in different print qualities, in economic quantities, matched to your application - at economic conditions.

As a leading label manufacturer and label printer for industry and trade, we not only offer you reliable quality in the production of self-adhesive labels, but also competent label advice on cost-effectiveness and efficiency for labelling solutions that suit your requirements, for example in product labelling and packaging.

Briefly describe your application to us - we will then be happy to work out the optimum solution for your application together with you in a personal meeting!