Canister labels - secure labelling for chemicals, cleaning agents and liquid building materials

Secure adhesion, durable, robust, chemical-resistant

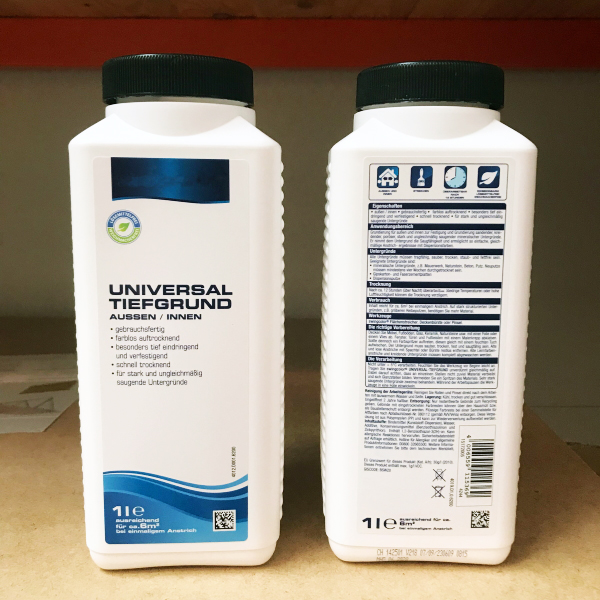

The usage scenario: Universal industrial canisters become customised product packaging with a chemical-compatible label

Plastic industrial canisters with screw caps are used as packaging for a wide variety of liquids: for example, cleaning agents for industrial requirements or construction chemicals such as impregnating and priming liquids.

The ‘milky’ or opaque appearance of the canister is typical, with a carrying handle and screw cap. These ‘neutral’ industrial canisters are procured in large quantities and filled with various chemical liquids and emulsions.

The material of the industrial canisters is usually HD-PE (high-density polyethylene), a shatterproof plastic that is highly resistant to acids, alkalis and other chemicals.

These canisters are available in different sizes, e.g. for filling quantities of 5, 10, 20 or 30 litres. The area available for labelling differs accordingly.

The smallest canister in this application example has a possible labelling area of approx. 180x240 mm. Labels of this size, or smaller, also fit on the larger canisters (which has an advantageous effect on the possible combinations of different print images in one order).

The label design, such as brand, product names, legally required declarations such as filling quantity and ingredients, as well as the required GHS labelling, differ depending on the contents of the container.

Industrial canisters are also available in opaque plastic, in a variety of colours. The solution described below is of course also suitable for this type of industrial canister, regardless of shape, size and colour.

The objective for this application is the economical procurement of different label layouts, even in small and medium runs. Robust labels are required that are resistant to the chemicals in the containers (including acids, alkalis and solvents).

The solution: canister labels on a roll, made of paper, polythene film or polypropylene film, printed using digital printing

For permanent labelling of the industrial container, the adhesive is the most important factor. Materials with a permanent acrylic adhesive with high initial and final adhesion are used, which can also be automatically labelled in high-speed filling systems. The adhesive adheres reliably and securely to smooth and rough surfaces of industrial canisters.

The label material used is just as important. Depending on the area of application and contents of the canister, paper or film (polyethylene, polypropylene or polyester) may be the right solution. If chemical and moisture resistance is required, film labels offer advantages over paper labels. However, paper labels can also be provided with an additional protective coating that makes the labels resistant to moisture. We work with you to find out which material is the most economical solution for your specific application.

To enable a pure recycling, a PE film is ideally used on the HDPE containers, which is also suitable for applying to curved surfaces. Depending on the print image and brand character, you can choose between white matt and glossy polyethylene films.

The roll labels are printed in short and medium runs using digital printing: this enables cost-effective production of short and medium runs, even with a wide variety of different print images. We print large runs particularly economically using UV flexographic printing.

For use on canisters whose contents must be labeled in accordance with the GHS regulation, we recommend film labels with an extra strong adhesive; they meet the requirements for seawater resistance in accordance with BS5609 Section 2.

The canister labels made of paper and film are suitable for the subsequent printing of daily production dates using thermal transfer printing (lot number, date of manufacture, expiry date, filling quantity, etc.). The high-quality material offers the best thermal transfer printing results for barcodes and small fonts.

The label size and shape are based on your specifications - we produce roll labels in your desired size.

Of course, we also offer product label solutions for oval and round plastic buckets with lids, such as those used for paints. These polypropylene buckets with their curved surfaces require particularly flexible label materials, ideally made of polypropylene, for unmixed recycling. We offer interesting solutions for labeling both the bucket and the lid to identify the contents.

Here too, inexpensive universal buckets, which can be ordered in large quantities, can be turned into individual product containers with a printed label, which is particularly interesting for small and medium-sized runs. Labeling solutions also offer significant advantages in terms of your warehousing and planning, as one roll of labels takes up very little space in the warehouse and can produce a large number of “printed” packaging and containers.

What is important for canister labels in the chemicals and building materials sector?

- Canister labels must adhere permanently and extremely well to the containers, as they contain important legally prescribed information.

- Depending on the intended use, resistance to chemicals (oil, acids, alkalis, solvents) is required

- Digital printing opens up economical solutions with a wide variety of types, even in small and medium runs

- Identical material labelling solutions are available for pure recycling (supporting the circular economy).

- Label shape and size precisely tailored to your needs and packaging system

- Adhesive with high initial adhesion: sticks securely, even at high labelling speed

NEW: Configure and order customised printed roll labels online!

With our online label configurator, you can easily configure your digitally printed roll labels and order them online immediately. Label size as required, made of paper or film, with protective coating or lamination if required. Just a few clicks to the price, upload your print data and send your order.

Customised printed labels for industrial canisters

We work with you to develop the right solution for your canister labels - from material selection to printing realisation.

We look for the most cost-effective solution based on your product, the variety of types and your labelling requirements.

Use the form to contact us and let us know your requirements!

Nous vous contacterons pour clarifier tous les détails !

Learn more about

Production process for digital labels

Hazardous substance labels and hazardous goods labels

Product labelling with paint bucket labels

Fewer packaging variants with paint can labels

Digital printing: labels for polyethylene bottles with tinting colour