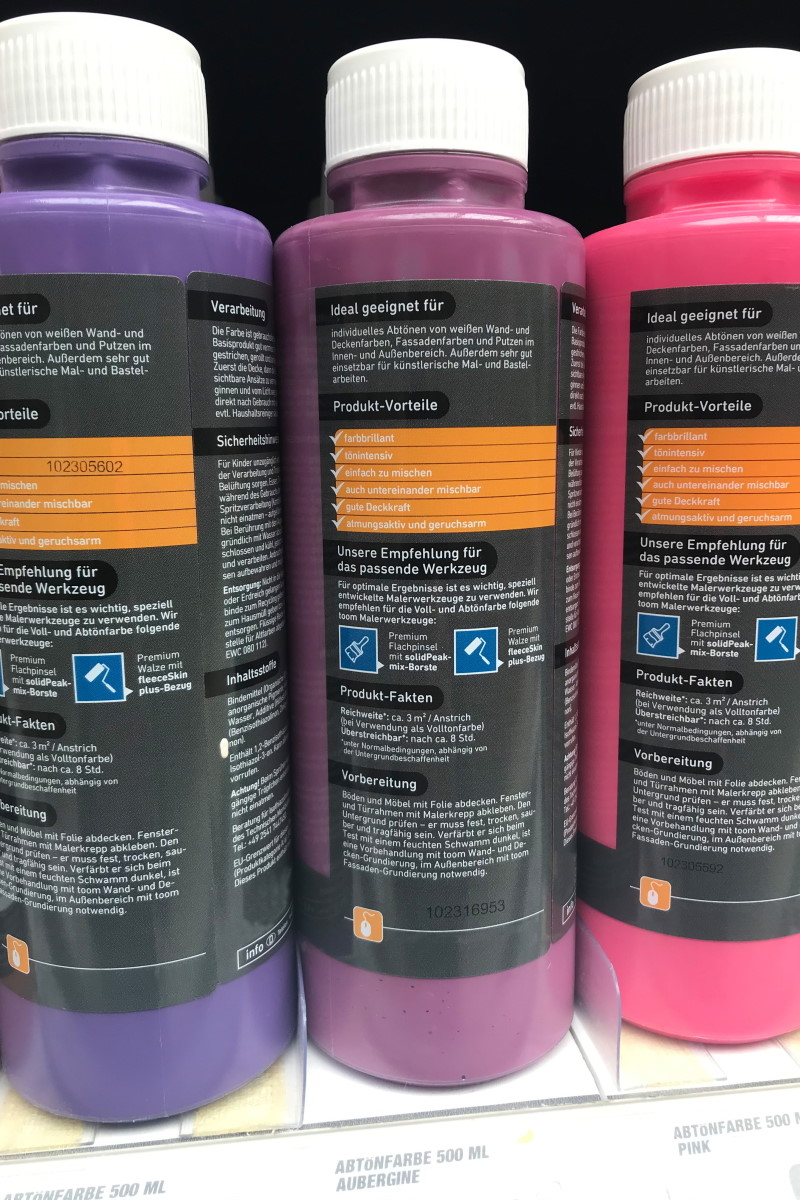

Tinting colour in PE plastic bottles with digitally printed labels made of transparent PE film

Full view of the colour content - and all important information printed at the same time

The usage scenario: digitally printed labels turn transparent colour bottles into individual product-specific containers

Colour bottles made of flexible PE plastic or, depending on the application, bottles made of PP are used for filling tinting colours. These tinting paints are used in the DIY sector to produce, for example, emulsion wall paints, silicate paints, lime paints and latex paints in the desired colour by stirring the brightly coloured pigments into the white paint.

These paint bottles are available in different sizes and are sealed with a screw cap. They are slightly milky or clearly transparent so that the tinting colour can be seen in the original.

They are purchased in bulk and serve as basic packaging for a variety of different colours. Only the label turns the universal colour bottles into an individual product.

The imprint of the labels, such as brand, product name, barcode, legally required declarations such as filling quantity and ingredients, as well as the required GHS labelling, differs depending on the content.

The advantage is that the universal bottles can be procured economically in large quantities. The labelling, in many different print designs, can often be produced in small and medium runs at economical conditions. Far more economical than completely article-specific printed coloured bottles. Together they form an economical and above all flexible packaging solution.

The paint bottles are made of polyethylene or polypropylene: robust plastics without plasticisers that are easy to recycle.

In this application, it is particularly important that the paint bottles are permanently labelled with wrap-around labels. This requires particularly flexible yet robust labelling materials that also adhere extremely well.

Ideally, the labels should be made of the same material as the paint bottle so that the emptied container can be recycled by type.

In this application, the focus is on the economical procurement of many different label layouts in small and medium runs. Robust, transparent film labels with high adhesion that are resistant to water and chemicals (e.g. solvents) are required.

The solution: Partially printed labels made of transparent PE film with strong adhesive properties

A full view of the contents - to achieve this, we use a transparent film label material that is partially printed in digital printing - with the best printing results thanks to the film surface optimised for digital printing.

The special feature of this label design is that large parts of the transparent label remain unprinted so that the contents are clearly visible to the consumer.

The ‘front’ offers a clear view of the contents of the bottle in large parts, with the brand and product name emphasised in white lettering on a black background.

A print image with white lettering on a black background was also chosen for the product information on the ‘back’ - this offers particularly good contrast and optimum legibility of the application recommendations and legally required declarations. The product benefits are highlighted particularly clearly on a bright orange colour field.

To create the white lettering, the areas that will later be printed in dark are printed in full white, after which the dark colours are printed with the corresponding cut-outs for the white texts.

Labelling the rounded bottle requires a pressure-sensitive adhesive with permanent, strong adhesion. Our PE material is characterised by high initial and final adhesion. This also enables machine labelling in automated filling lines at high speed. The labels adhere reliably to smooth and rough surfaces of the coloured bottles.

In this application, the label size has been selected so that it can be applied all the way round the coloured bottle without overlapping. For bottles with a more curved surface, a slight overlap of the label can also be useful

The highly flexible PE labels can easily cope with any deformation of the flexible plastic bottles (e.g. when pouring or squeezing out the tinting colour).

The use of PE film labels on the polyethylene bottles enables single-origin recycling when the paint container is empty. Depending on the print image and brand character, you can choose between matt and glossy transparent polyethylene films. White polythene films and polypropylene films are of course also available for other applications.

Our modern digital printing machines produce your product labels on rolls in the desired quantity, even in small and medium runs: this means that even with a large variety of types, different print designs enable cost-effective production of small and medium runs. We print large runs particularly economically using UV flexographic printing.

The high-quality PE film labels are even suitable for the subsequent printing of daily production dates in thermal transfer printing, for example with lot number, colour series, production date, expiry date and filling quantity. For this purpose, it is advisable to print the transparent film with a white ‘post-print field’ so that the print is easy for the consumer to read later.

The label size and shape depend on your specifications - we produce roll labels in your desired size.

Of course, this solution is also suitable for other products that are filled in transparent polyethylene bottles or polypropylene containers.

We also offer suitable labelling solutions for plastic canisters made of HDPE, such as those used for construction chemicals like primers, wallpaper primer or solvents. If you would like to find out more, visit our page canister labels.

We equip oval or round universal paint buckets, usually made of sturdy polypropylene material, with polypropylene labels just as economically; white or transparent film labels in various film thicknesses are available for this purpose. Find out more about paint bucket labels.

What is important for colour bottle labels?

- Labels for labelling tinting colour bottles must be robust and permanently affixed to the containers, as they also contain important declarations

- The labels must be able to withstand every movement of the flexible polyethylene bottle without peeling off.

- Depending on the contents, resistance to chemicals such as solvents may also be required

- The label shape and size are customised precisely to your requirements and packaging system

- Label materials of the same material are used to support the circular economy through pure recycling

- The production of colour-printed roll labels using digital printing is an economical solution with high print image diversity, even in small and medium print runs

- The adhesive with high initial and final adhesion is also suitable for high labelling speeds in the filling line and adheres permanently and securely

NEW: Configure and order customised printed roll labels online!

With our online label configurator, you can easily configure your digitally printed roll labels and order them online immediately. Label size as required, made of paper or film, with protective coating or lamination if required. Just a few clicks to the price, upload your print data and send your order.

Partially printed transparent labels for colour bottles with tinting colour - robust, chemical-resistant, secure adhesion

We will work with you to find the right solution for your colour bottle labels - from the material to the printing.We pay particular attention to finding an economical solution, tailored to your product, the variety of types and the required label quantities.

Of course, this solution is also suitable for other products that are filled in transparent plastic bottles.

Use our form - to get in touch with us - we look forward to hearing about your specific requirements!

Learn more about

Production process for digital labels

Hazardous substance labels and hazardous goods labels

For chemicals, cleaning agents and liquid building materials: canister labels

Fewer packaging variants with paint can labels

Product labelling with paint bucket labels