Batch identification in the food industry

Labels as reliable sources of information

Food regulation at EU level ensures food safety throughout the entire product chain – and also regulates the information and recall obligation in the event of quality and safety defects in specific product batches.

This vital aspect of quality management contributes significantly to the protection of consumers’ health. In the event of contamination of foodstuffs, the place of origin can be rapidly identified and the batch concerned can be traced and withdrawn from circulation as soon as possible.

If a foodstuff is found to present a risk to the consumer, the products of a defective batch can then be recalled from the market. The individual processing and delivery steps must be fully documented. At each stage of the food chain, the immediate upstream supplier and the immediate recipient must be documented to provide the authorities with the relevant evidence.

The usage scenario: batch identification for beef

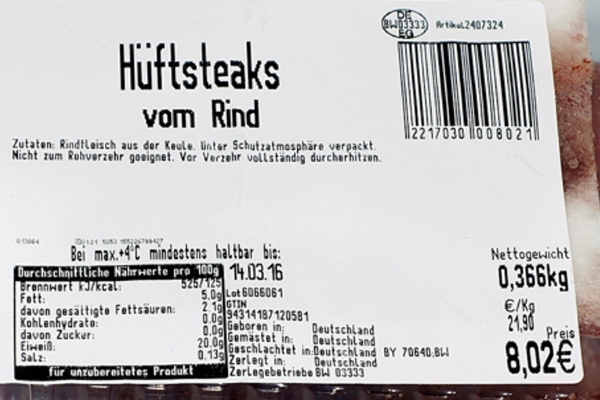

An interesting example here is the labelling of beef:

Beef labelling is uniformly prescribed in every EU country. The label contains information on where the animal comes from and where it was slaughtered and cut.

All the information must be clearly visible to the customer and correctly assigned to the beef in question.

The reference number or code ensures the traceability of meat. This number may be the identification number of the animal or the identification number of a group of animals (batch). Only animals from one slaughterhouse may be included in the batch.

Details such as ‘Born in...’, ‘Raised (fattened) in...’, ‘Slaughtered in...’ and ‘Cut up in...’ describe the origin and history of the product.

The approval number of the slaughterhouse and cutting hall clearly identifies the further processors.

The solution: labels on rolls for thermal transfer printing, with special ‘low-migration’, pressure-sensitive adhesive

As a source of information, the label plays an indispensable role in meat labelling.

It must adhere securely on surfaces of all kinds – and it must also function safely in the deep-freeze area and in humid environmental conditions.

Added to this are the requirements for food conformity. Using its adhesive material in-house production, HERMA has designed ‘low migration’ label solutions especially for these usage scenarios.

Thermal transfer printers are ideal for printing these labels on rolls, providing the best possible printing results for easy barcode readability.

The adhesive has a powerful tack and strong final adhesion, even in humid or cool production environments – superb for reliable labelling, even at high packaging speeds in fully automatic labelling systems.

But our food labels are not only the best information carriers for meat labelling. Discover the benefits of HERMA food labels for a wide range of food labelling applications.

The outstanding features of this solution:

- Blank labels on rolls, in your desired format

- Ideal for printing with thermal transfer printers

- Adhesive suitable for film packaging, even in humid or cool environments

- Food-compliant label paper and adhesive

Batch labels, tailored to your requirements - we will be happy to advise you!

Batch labels are found on packaging and surfaces of all kinds: folding boxes, egg cartons, frozen goods, pasta packaging, meat packaging, ...

So the requirements for these labels differ greatly: depending on the surface and usage scenario, we can offer you label materials that are optimally matched to your requirements

Contact us – we’ll be happy to develop the right solution for your label requirements, in your desired format.

Learn more about

Features and benefits of our labels for food labelling

For thermal transfer and direct thermal printers: Blank roll labels