Security against counterfeiting in the pharmaceutical industry

Serialisation with laser-activated labels from HERMA

The prerequisite: individual labelling with a security feature

Counterfeit products and product piracy are serious problems for the pharmaceutical industry. If a counterfeit medicine is sold to customers, they may develop health issues – and they will probably lose confidence in the product or brand. Lured by the enormous profit margins, medicine counterfeiters often dilute, omit or replace ingredients with ineffective or even harmful substances.

To prevent this, a February 2019 directive stipulates that all prescription medicines in the EU must be provided with a security feature that enables wholesalers and pharmacies to check the authenticity of the product in question. This individual identification is also known as ‘serialisation’.

In the form of a 2D data matrix code, the security feature (‘unique identifier’) ensures the traceability of the packaging along the entire supply chain. The main code contains the product code that identifies the drug, the serial number with a maximum of 20 digits, the national reimbursement or identification number, the batch number of the medicines and their expiration date. If a recall is necessary, the batch number can be used to check which products are affected and to initiate appropriate measures.

In addition to the machine-readable code version, the product code and the serial and reimbursement numbers must also be legible – inscribed in plain text printed on the medication packaging. A seal on the package providing evidence of unauthorised opening (e.g. a HERMA tamper-evident label) completes the requirements of the directive.

To check the validity of a serial number, the serial numbers are uploaded by the pharmaceutical company or contract packager into a database system, to which dispensers of the medicines (such as pharmacies and hospitals) have access. When a drug is dispensed to a consumer, a scan and verification query is performed to check whether or not the serial number is available in the database. If it is, the drug is authentic.

The solution: labelling systems offer many advantages for the serialisation of medicines

The security feature can be printed on the folding box itself, or labels for serialisation can be used – this offers advantages because not every folding box can be printed equally well with every printing process. Different printing processes must be used, depending on the material used for the box and the embellishment.

If different pharmaceutical packagings have to be processed in a pharmaceutical company’s production packaging line, this places additional demands on the printing system. Labels are generally more suitable for this purpose because they always place the same demands on the printing system – and they can be processed at the same speeds in the packaging line – so a large number of different folding boxes can be labelled with just one type of label – and always under the same conditions.

To ensure a readable code that will ultimately guarantee pharmaceutical security without any duplication of serial numbers on the packaging, all the parameters must be perfectly matched to one another: labels, printing system and labelling unit in the packaging line.

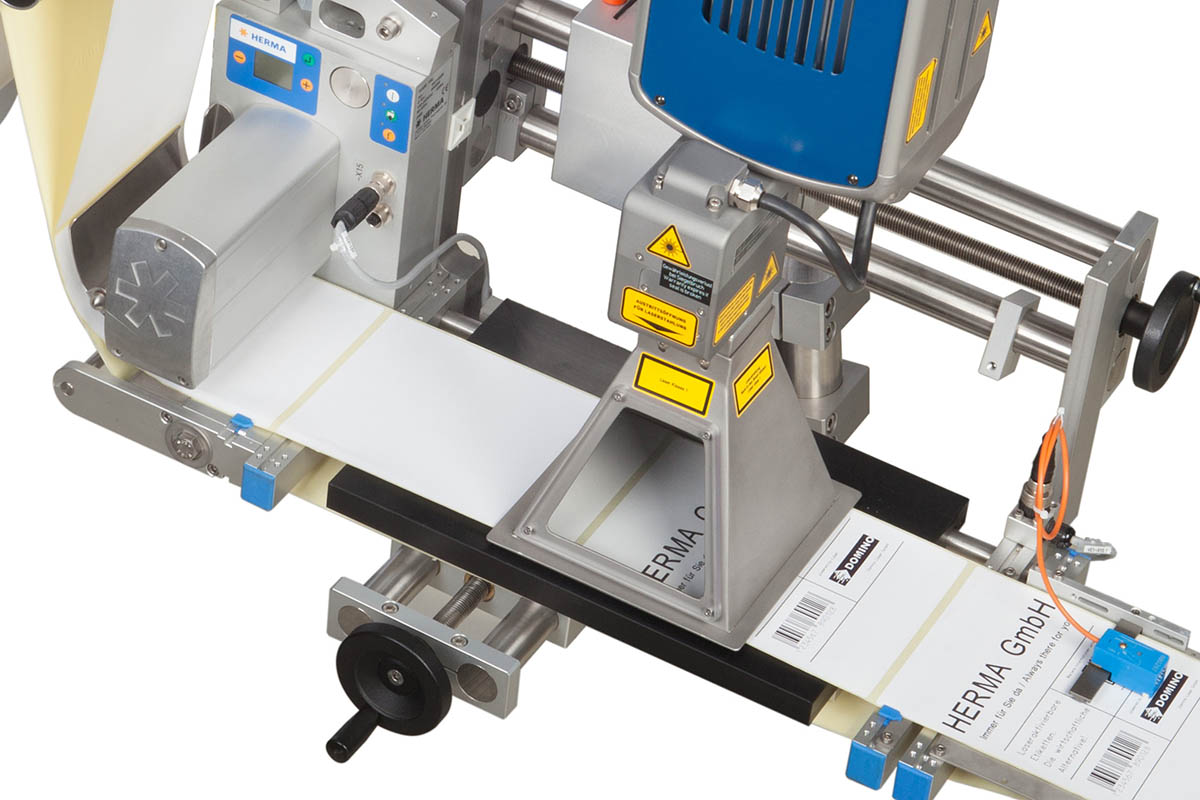

For this usage scenario, HERMA offers not only labels, but also the corresponding printing systems and labelling units, all integrated into the packaging lines – a system solution completely customised to the packaging requirements of the pharmaceutical sector.

Integrated camera systems ensure the required security during the packaging process.

Laser-activated labels (LAM) offer many advantages

Laser-activated labels are printed and dispensed directly in the packaging line(s) and offer a number of advantages: equipped with special finishing, they can be ‘marked’ black with a laser in the labelling system itself – absolutely smudge-proof and scratch resistant. The typeface is razor-sharp, even with the smallest font sizes in plain text, graphics and/or codes. For example, Asian characters can be difficult to inscribe, but the lettering is always crystal-clear. The print is never blurred, and the label is undamaged. The laser system is not subject to wear and tear and requires no additional consumables, thus reducing production downtimes.

However, conventional thermal transfer printing systems and the matching labels on rolls for thermal transfer printers can be used.

Tamper-evident solutions from HERMA

Special tamper-evident labels are a simple and flexible way of providing proof of product authenticity and clear evidence if the seal has been broken. In this way, existing folding boxes can be used again and again without the box design having to be changed. These security labels permanently affix the tuck-in flap to the body of the box, offering the required protection against manipulation. Another decisive factor here is the label adhesive. These labels are always ruined if they are removed, even from painted surfaces. Only an undamaged label is a guarantee that no unauthorised opening has

We will be happy to advise you – just get in touch with us.

What’s special about laser-activated labels for this usage scenario?

- Labels provide identification for a multitude of different folding boxes

- System solution: labels, printing system and labelling unit, all from one source

- Laser-activated labels: razor-sharp print image, ideal for data matrix codes

- Wear & tear-free, no additional consumables

- Highest level of process security

- Tamper-evident labels as proof of unauthorised opening

Customised for your usage scenario – we’ll be delighted to advise you!

Thanks to our in-house adhesive material production, we can specifically respond to a wide range of your label usage requirements – and we’ll find the perfect solution for you every time.

We’ll give you personal advice to help you find materials that are ideally suited to your specific needs. Use the contactform to let us know what you need.