The usage scenario: Labelling vaccine labels with variable data directly during the filling process

The reliable and secure labelling of vaccines in injection bottles, known as vials, poses particularly high challenges.

- The vaccine labels must adhere firmly and permanently to the small-diameter containers/vials.

- They must withstand demanding conditions during labelling in the filling process and storage in the cold chain.

- The vaccine label itself must be robust and flexible at the same time.

- And last but not least, the print must be smudge-proof, scratch-resistant and permanently legible.

What information must be included on a vaccine label?

In addition to the product name, description, number of vaccine doses and fill quantity (fixed data), a vaccine label on a vaccine vial must also contain particularly important variable data, such as the lot number and expiry date. A data matrix code contains all important information in machine-readable form.

The wealth of information on a small-format label can only be achieved by using relatively small fonts.

The variable data, especially the lot number, is extremely important for the safety and traceability of the vaccine and must be permanently legible.

Since this variable data differs for each production batch, it should be printed directly onto the vaccine labels during the filling process.

The high filling speeds in vaccine production require a printing system that can keep up with the high cycle rates.

What is needed is a flexible labelling solution that can be reliably integrated into the filling system – while also offering high cost-effectiveness.

The solution: flexible, contactless printing of vaccine labels using UV laser technology

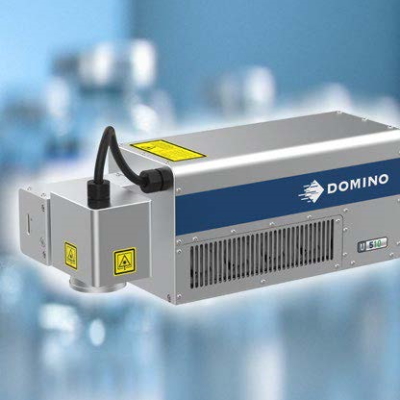

HERMA offers a unique system solution for this highly demanding application: the HERMA pharmaceutical labelling machine 132M HC, in conjunction with a Domino UV510 UV laser, prints and dispenses UV laser labels specially developed for this application onto the vials. Other UV laser printing systems also deliver excellent printing results on HERMA PE UV laser labels.

The UV laser labels master the high requirements for vaccine labelling with flying colours:

- PE film labels with UV laser-activated components – no dyes

- Robust, flexible and supple: easy application to curved surfaces, even with small diameters

- Visually attractive glossy surface with high opacity

- The special adhesive sticks firmly and securely to the injection vials and is also suitable for low temperatures and freezing processes

- The lettering produced by the UV laser is completely smudge-proof and scratch-resistant and resistant to disinfectants, alcohol and grease

- The UV laser allows lettering or characters that are only 0.6 millimetres high – the print image is always razor sharp, even with the smallest font sizes

How does printing vaccine labels with a UV laser work?

1. Label properties

The vaccine labels are made of a special white PE film that reacts to UV light with a colour change. This is an important prerequisite for the laser printing process.

2. Generation of the laser beam

The system generates a high-energy UV laser beam. This laser operates without contact, i.e. without touching the label, and does not require ink or ribbons.

3. Chemical reaction in the label material

When the UV laser beam hits the film label, a chemical change occurs. This change triggers a colour change in the material itself and ensures a permanent marking.

4. Creation of the print image

Thanks to the precise control and high speed of the laser, a complete print image is created in a fraction of a second. This extremely fast labelling can keep pace with the high filling speed in vaccine production.

5. Result: high contrast and machine-readable

The result is a dark grey, high-contrast typeface on the white label. It is not only easy for humans to read, but also ideal for scanners and machine-readable systems.

6. Advantages in the production process

No additional consumables are required, neither ink nor ribbons. The process is resource-saving and cost-efficient compared to the thermal transfer printing that has been widely used to date. The laser operates without contact and with low wear, which reduces downtime and maintenance costs. The marking speed is significantly higher than with thermal transfer printing and is therefore particularly well suited to the high cycle rates in vaccine production.

Take advantage of our system expertise and receive comprehensive advice on vaccine labels for maximum efficiency in your vaccine production process.

Variable labelling of vaccine boxes

The vaccine vials are packaged in folding boxes. Inside, custom-fit inlays ensure that all product components are securely fixed in place. This means that the vaccine doses are safely protected during storage and transport. Vaccine labels are also a secure solution for labelling vaccine folding boxes. And just like with the vials, variable data must also be printed here for traceability.

Laser-activatable paper labels, for example, are suitable for this purpose. They can be printed and applied directly in the packaging system using a CO2 laser.

Learn more about LAM labels for CO2 labelling systems: Laser Labels

Labelling outer cartons and transport cartons for vaccines safely and economically

Many vaccines must be stored at specific temperatures to maintain their effectiveness. Cardboard thermal shipping containers are generally used to ensure that the cold chain is maintained during vaccine shipping. The vials are packed in smaller folding boxes and cartons. For vaccines that must be stored and delivered at particularly low temperatures, the thermal containers also contain dry ice pellets.

The labelling of this secondary vaccine packaging must also be secure and permanent. Here, too, CO2 laser-activated paper labels can be used for the efficient printing of logistics labels directly in the packaging systems at high speed.

Learn more about LAM labels for CO2 labelling systems: Laser Labels

The advantages of HERMA UV laser vaccine labels at a glance:

- Low-maintenance and contactless printing, virtually wear-free, no additional consumables required, e.g. for thermal transfer printing

- A complete print is produced in a fraction of a second by colour change, ideal for high cycle rates in vaccine production

- Pin-sharp print image and typeface, with high contrast, even for very small fonts and characters on the vaccine label

- Ideal for labelling with expiry date, batch number, lot number and fill quantity, in plain text or codes

- Resistant to disinfectants, alcohol and grease, moisture, soaps and oil

- Very well suited for very low temperatures, including freezing processes; the labelling on the vaccine labels remains clearly legible

Vaccine labels: We are happy to advise you!

HERMA UV laser labels made from high-quality white PE film are the ideal solution for vaccine labelling with variable data – directly during the filling process in vaccine production. They can be printed on with all UV laser printing systems and offer the highest quality in terms of speed, contrast and contour sharpness – with clear advantages over conventional thermal transfer labels.

Get in touch with us for comprehensive advice!

HERMA also offers high-quality labels for other printing systems. Blank paper labels are often used, which can be printed on with different printing systems.

Find out more on our pages

Shipping labels and pallet labels

On roll: Thermal transfer labels

On roll: Thermal labels

On sheets, rolls or fanfolded: Blank labels

You might also be interested in:

Traceability for medicinal products and medical devices: Batch management with UDI labelling on medical labels

Protection against the unauthorised opening of medicines with tamper-evident labels for counterfeit protection