Self-adhesive materials for the pharmaceutical industry

Labelling of containers with small diameters

Small-diameter glass and plastic containers present special challenges when it comes to labelling. In the case of plastic containers, it is also possible for plasticizers and similar substances to migrate into the label and impair the function of the adhesive. Plastic is generally considered more critical in this respect than glass on account of its non-polar surface, which can impair adhesion. HERMA adhesives for pharmaceutical labels were developed specifically for these applications. When used in combination with thin label materials, HERMAperfectStick (63Mps) is perfectly suited for critical applications with diameters less than 15 mm. Continuous improvements in the productivity of labelling systems are placing greater and greater demands on labels. Labels are applied by means of high-speed machinery and in some cases must adhere to cool surfaces. HERMA pharmaceutical adhesives are easy to process and dispense, and they retain their high adhesion even at low temperatures. The critical factor is perfect interplay between the adhesive and the label material. Our materials for pharmaceutical applications are therefore flexible, thin and adaptable. You’ll find the ideal solution for every task.

Migration-safe adhesives for pharmaceutical labels

All HERMA adhesives for pharmaceutical labels are also certified for direct contact with foodstuffs.More and more pharmaceutical manufacturers are switching from glass containers and bottles to packaging made of plastic. HDPE and LDPE offer a number of important advantages, including low production costs, squeezability and impact resistance. This trend has greatly increased the risk of migration. With plastic containers, substances in the packaging material can migrate through the plastic and contaminate the pharmaceutical product. HERMA has specialised in the production of migration-safe adhesives for many years. Our innovative multi-layer coating technology plays an essential part in the manufacture of many adhesives. The middle layer is extremely migration safe, but this has no effect on the adhesive properties and processing characteristics that are required in the pharmaceutical industry

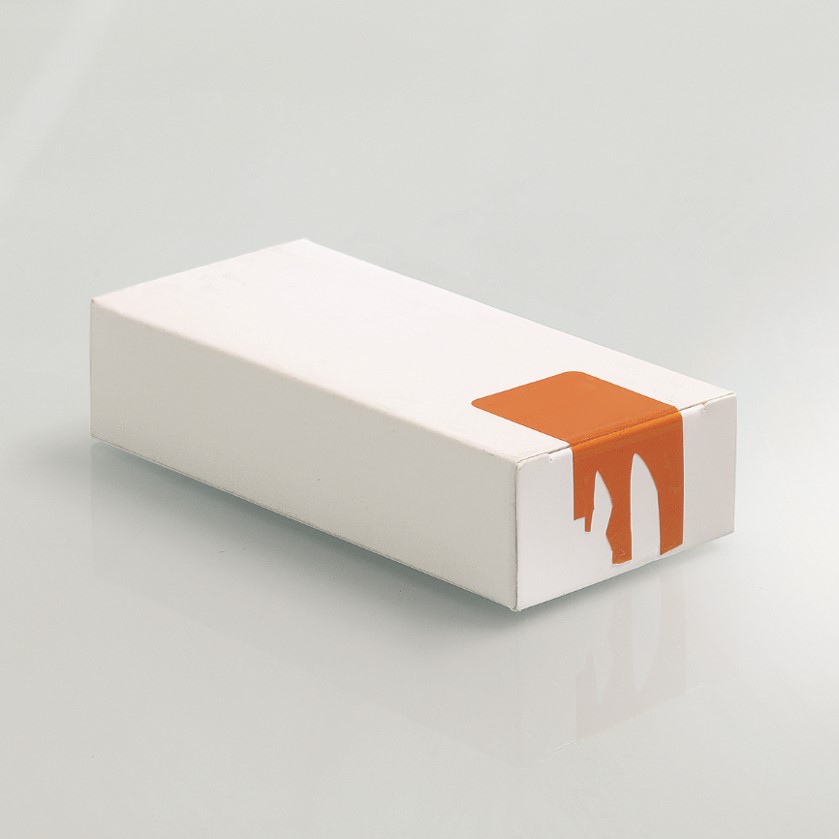

Economical tamper-evident solution

The adhesive (63Spc) opens up a wide range of possibilities for low-cost, tamper-evident packaging of medicines and other products. The new Regulation 2016/161/EU requires the placement of such anti-tampering safety features on medicinal products subject to prescription. The final adhesion of adhesive (63Spc) is so high that when it is used for seal labels on boxes with dispersion coatings and on many other polar and non-polar surfaces, such as paper, cardboard, plastic and steel, the labels cannot be removed without destroying them or leaving a residue. This function can be enhanced by means of safety perforations in the label.

Highly resistant

(63Spc) is highly resistant to water, solvents and hot air. Tampering by means of hot-air blowers is therefore impossible. This adhesive is also very resistant to ageing. Since it is a dispersion adhesive, adhesive materials used with it are easy to process even when relatively large amounts are applied.

Economical

Costly special materials like self-destructing films, holograms, cellophane wrappers, VOID solutions or completely new collapsible box designs are no longer required.

Our advantages

• Over 110 years of Made in Germany

• High level of service

• State-of-the-art coating system

• Innovative multi-layer coating technology

• Best product quality in maximum availability

Individual requirements

• Extremely strong adhesion

• Labelling of curved surfaces with small radii

• Labelling around corners

• Tamper-proof

• Resistance to damage

• ISEGA certification for direct labelling of blood bags

• Luminophores in the adhesive material (optical brighteners for label detection)

Advantages - Economical tamper-evident solution

• Economical

• Age-resistant

• Perfect dispensing characteristics

• Resistant to water, hot air and solvents

• Suitable for a wide range of surfaces

• No running of adhesive at the edges

• Certified for direct contact on dry and moist surfaces

Our solution for you

We offer the right solution for every pharmaceutical application. This is made possible by our extensive product portfolio, which consists of a wide variety of labelling materials and special pressure-sensitive adhesives. The innovative multi-layer coating technology enables the best adhesive properties under the most difficult conditions. In addition, minimised adhesive tolerances ensure even greater reliability throughout the entire process chain.

Our standard pressure-sensitive adhesives 62A, 62D, 62Z, 63B and 63Z have ISEGA approval for direct blood bag labelling. All our standard pressure-sensitive adhesives have ISEGA approval for direct food contact and are therefore completely safe.

A list of all adhesive composites suitable for the pharmaceutical industry can be found in our product catalogue on page 42.

Catalogue